The Reason

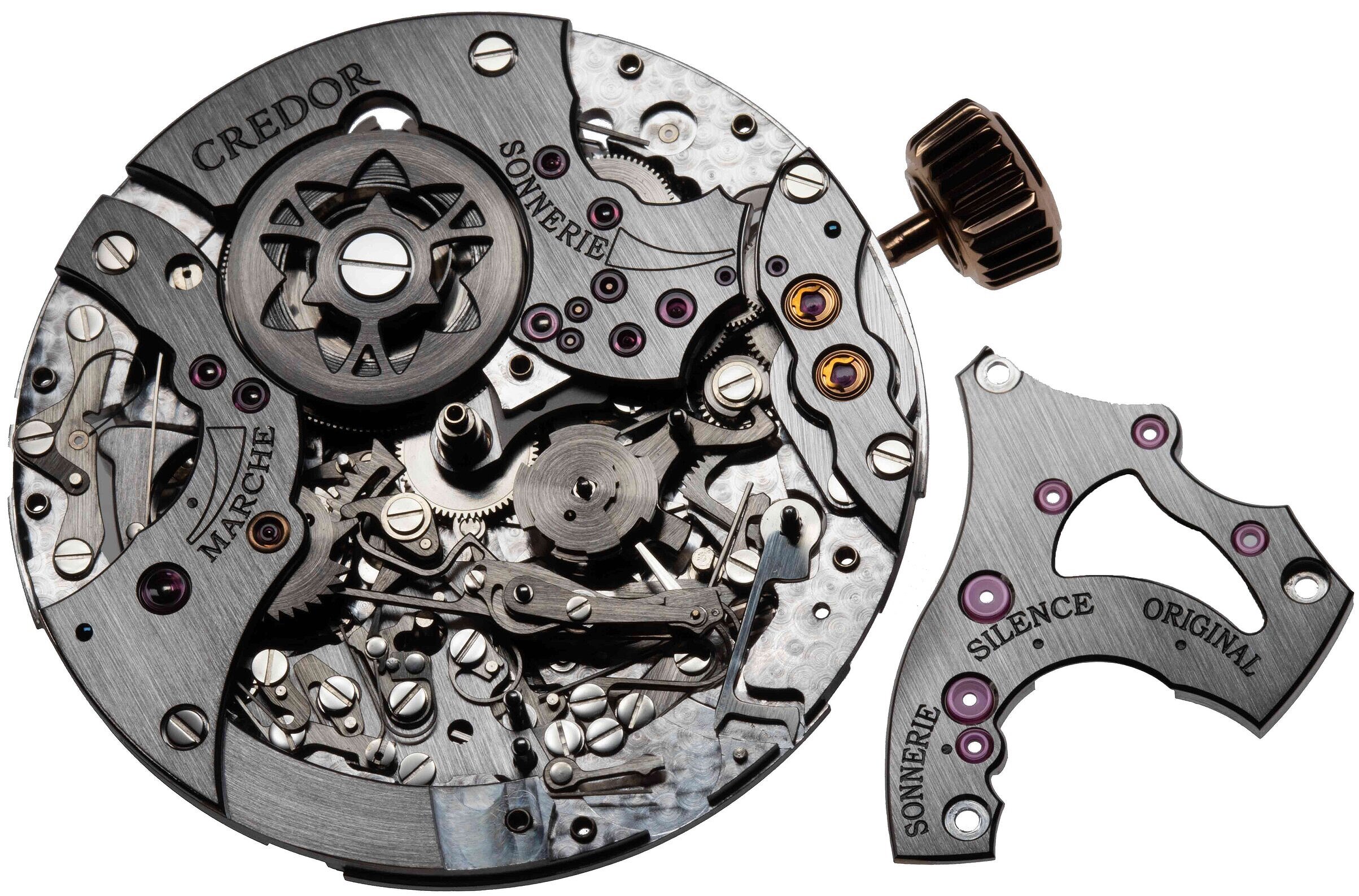

A unique “Sonnerie” wristwatch in function and philosophy.

A note regarding this deconstruction

The Credor Spring Drive Sonnerie deconstructed below was made in 2006 and was one of the first prototypes to be made of the Sonnerie. Although identical to the later versions aesthetically, there are slightly fewer components in this version than those that followed. This watch was working perfectly prior to the deconstruction and had not been dismantled during the preceding years.

Introduction/Functions

The Credor Spring Drive Sonnerie was launched at Baselworld in 2006. Produced at Credor in Shiojiri, Japan. The watch is driven by a Seiko’s unique manual Spring Drive movement, whose power comes from the unwinding force of the mainspring as with a traditional mechanical watch, but delivers a higher level of precision than the majority of mechanical watches can provide due to its tro-synchro regulator. The tri-synchro regulator applies electro magnetic braking to its glide wheel based on the accurate reference signal from the IC and quartz oscillator. (More details concerning the Spring Drive can be found here).

The “7R06” sonnerie calibre automatically hits the bell found in the back of the watch three times every 3 hours at 12 o'clock, 3 o'clock, 6 o'clock, 9 o'clock when in ‘Original’ mode. When the Sonnerie is deactivated the selection hand points to ‘Silence’. When in ‘Sonnerie’ mode the hours are sounded every hour on the hour.

An “hour repeater function” causes the hammer to strike the bell at the current time whenever the button at the 8 o'clock position is operated manually. The 2 o'clock and 10 o'clock positions visible on the movement dial side, show power reserve indicators for the going train and Sonnerie.

The Credor Sonnerie (dial side)

The Credor Sonnerie (case back held in place by 6 screws)

Explanation of the 3-hour intervals.

The presence of the 3-hour interval mode is linked with early Japanese cultural history, before clocks and timekeeping existed as we understand them today. The cycle of life in Japanese towns varied from season to season, depending on the length of the day which was influenced by the amount daylight within a day. The bell in the temple was sounded to indicate regular intervals during the working day, although always varying in length during the year; by today's calibrated time we can average the interludes to 3-hour intervals between the bell being struck.

The Orin bell both influenced the technical and cultural approach behind the Sonnerie. Technically, to develop a clean resonating sound, and culturally, the ‘original’ mode setting sounding the bell 3 times every 3 hours (explained above).

The Credor Sonnerie selection hand. Modes: SONNERIE striking the hours on the hour, SILENCE deactivates the sonnerie, ORIGINAL the gong is struck 3 times every 3 hours.

Technical Specifications

The Credor Sonnerie calibre 7R06 photographed in this deconstructions was made in 2006, it varies slightly from the today’s version. It has 616 parts in the movement compared to today with 632. Number of jewels, 88.

Case material 18K pink gold. Sapphire glass (with anti reflection coating). Accuracy, monthly variation ± 15 seconds (daily variation ± 1 second equivalent). Size, vertical (inc shoulders) 51.0 mm, diameter 43.2 mm, thickness 16.3 mm. Weight of complete watch 155.0g.

The Credor Sonnerie profile showing selector button.

The gold case back removed showing the milled out sections on the inside allowing the sound to be clearly heard.

The case back removed showing the fine mesh cover (made using MEMs technology).

The fine membrane covers the gong preventing small particles entering the movement but allowing the sound to be clearly emitted.

The protective fine mesh disc removed.

The miniature Orin bell removed from the movement.

The 5 large holes access the screws holding the bell in place on top of the calibre.

The side hole to allow the stem access to the movement.

The inner metal piece that supports the bell and is screwed to the calibre.

The bezel removed allowing access to the movement.

There is no dial so that the full movement can be viewed. There are milled out hours markers on the inside of the bezel below the sapphire.

The rear of the movement outside of the case and the bell removed.

The movement (dial-side) removed from the case.

The empty case, and case pusher dismantled.

The skeletonised barrel is designed in the form of the Shiojiri town flower. The form of the bridges around the barrel have been cut to resemble a river down which the Bell flower would traditionally travel.

The simple straight grain and circular finish allows the form of the bridges and the mechanism to be viewed easily. Although aesthetically simple, this type of finish is very delicate and complicated to execute consistently and evenly. If during the assembly a bridge is only very slightly scratched, the mark will easily be seen in contrast with the overall satin finish and the bridge would need to be replaced or refinished.

Both power reserves (going train and Sonnerie) originate from a single barrel. The power reserve for the Sonnerie is 45 hours and 60 hours for the going train.

All of the hands are made from steel, polished and blued by heat treatment.

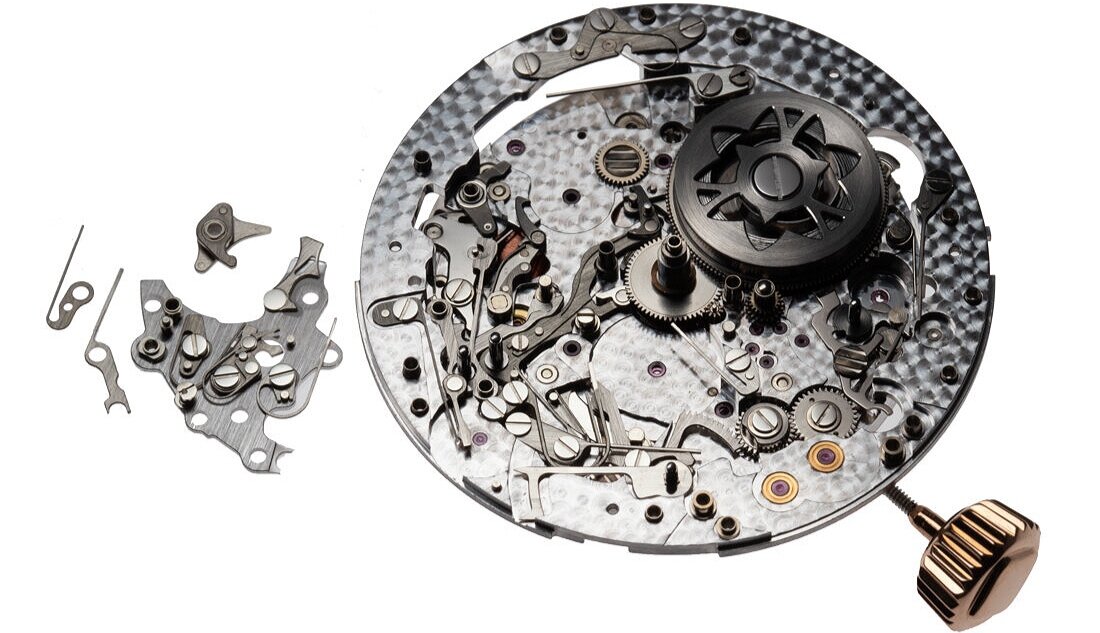

The hands removed and beginning to remove the bridges starting with the retrograde power reserve for the going train.

The bridge covering the selection device removed.

The primary Sonnerie train bridge removed.

The bridges and mainplate are made from German Silver and rhodium plated after decoration.

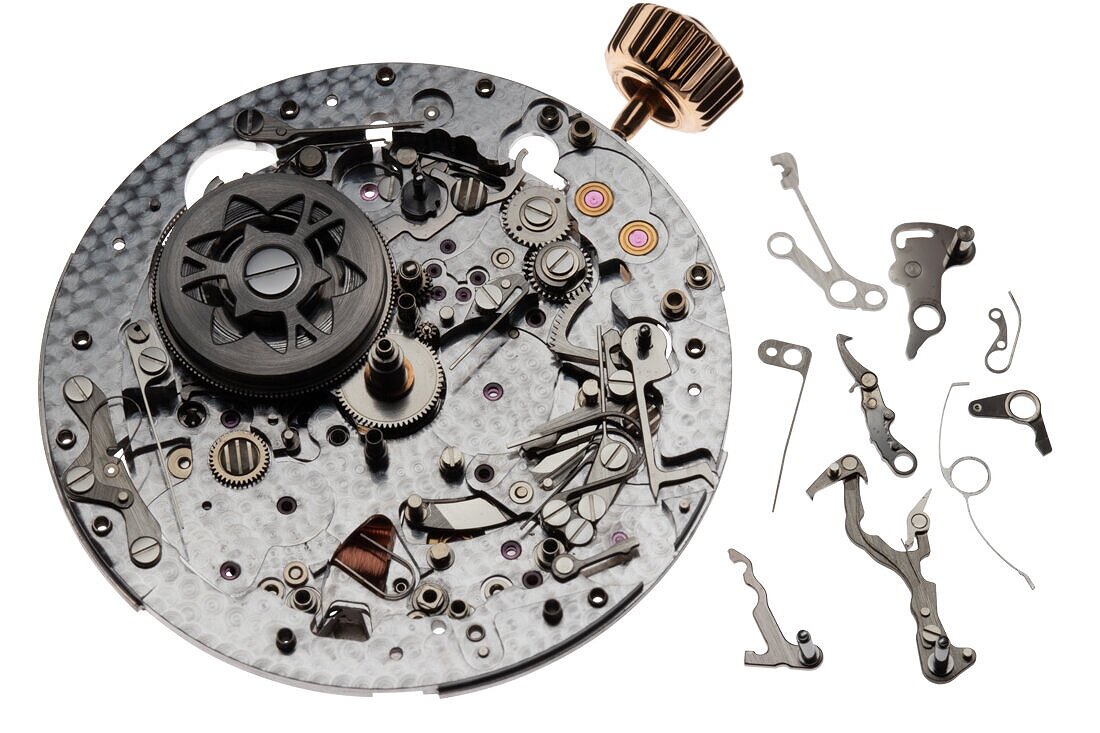

The large multi-layered lever below the snail shaped cam is the primary operating lever that drives the ratchet wheel activating the hammer that hits the Orin Bell.

The Credor Sonnerie primary operating lever.

Below is one of the most complex assemblies in the mechanism, which activates the hammer.

The bridge holding the hammer in place removed.

The hammer can be seen at 8 o’clock.

The central snail shaped cam controls the hour striking function and dictates the number of hours to be struck in Sonnerie mode.

The Sonnerie mechanism is built on approximately 12 different levels, with racks, springs and levers isolated between layers.

Congruently with the silent running of the Spring Drive going train of the movement, the braking system governing the speed of the hammer striking, is controlled by the centrifugal assembly shown below.

The bridge to the right cover the brake/governor.

The various stages of assembly of the brake/governor.

The brake/govenor dismantled

The outer diameter of the brake/governor is 4mm

The complex MEMs governor spring

The brake/governor incorporated into the sonnerie mechanism makes use of the air viscosity to make it silent while functioning, to avoid the sound of the Orin bell being obscured.

The assembly of the brake as with the entire movement is executed manually by watchmakers. The complete process requires several months of hand assembly, once the components are made and decorated. The time required from the beginning of a new series of Sonneries including manufacture of all parts and decoration, until the first are completed is approximately 8 months.

A large series of gears that drive the Sonnerie and lead to the brake/govenor removed.

The construction of the mechanism is unlike any other that exists today or has ever been built. It is more complex than a Minute Repeater with more components, closer to the amount of time required to build a Grand Sonnerie.

Below: The snail shaped hour cam sitting on top of the 3 hours selection cam, both held together and indexed by the hour star wheel to their left.

The hammer (to the left) removed.

Recto-verso of the hour rack that drives the hammer. The 12 small teeth trip the hammer, the two large teeth either side limit the maximum movement of the rack pushing switches to stop its movement once it has sounded the time.

The hammer striking the bell is made from brass, hand finished then plated with rhodium. The choice of brass is to protect the longevity the of the bell.

The small piece on top of the hammer is the trip that the ratchet wheel pushes against to activate the hammer.

Nearing the full disassembly of the movement, a German silver bridge that both covers additional levers and springs as well as supporting many is removed.

The Sonnerie continues to be dismantled. At 6 o’clock on the image below can be seen for the first time a view of one of the copper coils linked with the going-side of the watch, that are assembled from the back of the watch.

When the movement is developed, and assembled for the first time the watchmaker building the calibre works closely with the constructor to fully understand the functions of the plethora of springs and levers and their interaction with the mechanism around them. The feedback returned to the constructor from the watchmaker will alter certain elements of the construction enhancing performance, facilitating assembly etc. This process continues during the life-span of the production of the calibre but is never as substantial as during the first assembly.

The mainplate with the majority of the parts removed including the barrel.

Summary

The Sonnerie includes safety mechanisms to prevent any damage occurring when the Sonnerie is activated and adjusted simultaneously. The combination of the 'clock watch function', striking on the hour, the number of hours plus the option of 3 hour intervals announcements from the watch, coupled with the hours being sounded manually on request, results in a highly complex mechanism. The watch links Credor's ability to develop a highly complicated timepiece with aesthetic and functional associations to Japanese culture. The Spring Drive system is found under the complication and the bell.

(For a detailed explanation on how the Spring Drive functions please see the Grand Seiko deconstructions)

To learn more about Credor