The Reason

The simple but original system of transmission of power between the two barrels extending the basic power reserve of a simple manual wound time piece to 90hours combined with a general skeletonised design aesthetic.

The name "Nebula" (Latin for "cloud") was selected because with its bridges designed from the perimeter of the dial toward the centre, the movement looks like an inverted, exploded star. Nebulae, an astronomical term describing a cloud of cosmic gas and dust, are formed from the debris of exploding stars and constitute the regions in our universe in which new stars are born.

Technical. A&S 5101

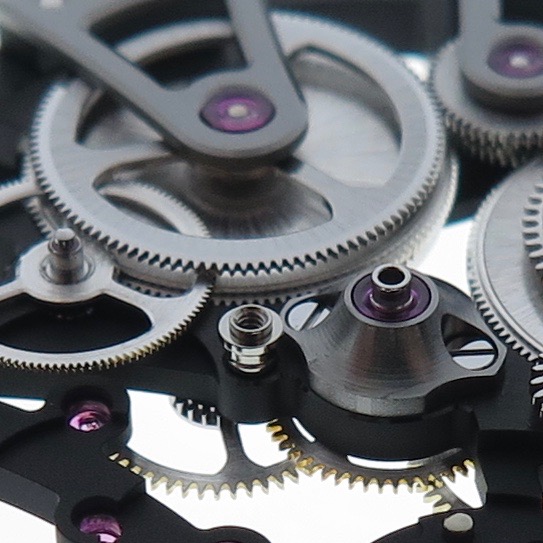

Manufacture calibre, skeletonized, hand-wound, 24 jewels, diameter 31.50 mm, two mainspring barrels, screwed balance wheel, thickness 4.04 mm, power reserve 90h, 3 Hz / 21,600 vph, adjusted to 5 position. Movement decoration: NAC-treated bridges and black ADLC-treated main plate. Chamfered bridges with polished edges and brushed surfaces, gold chatons, screws with bevelled and mirror-polished head.

In 2016, there were approximately 75 Nebula watches made 50 in steel and 25 in red gold.

Rear view of the assembled calibre, conventionally this would be the side that is hidden under the dial but in this design the calibre is reversed and the hands driven from the back of the watch.

Inclined profile image of the movement prior to being cased

Once the screws have been added to the movement a torque wrench set at a high couple is used to ensure the screws are tight.

The assembled calibre

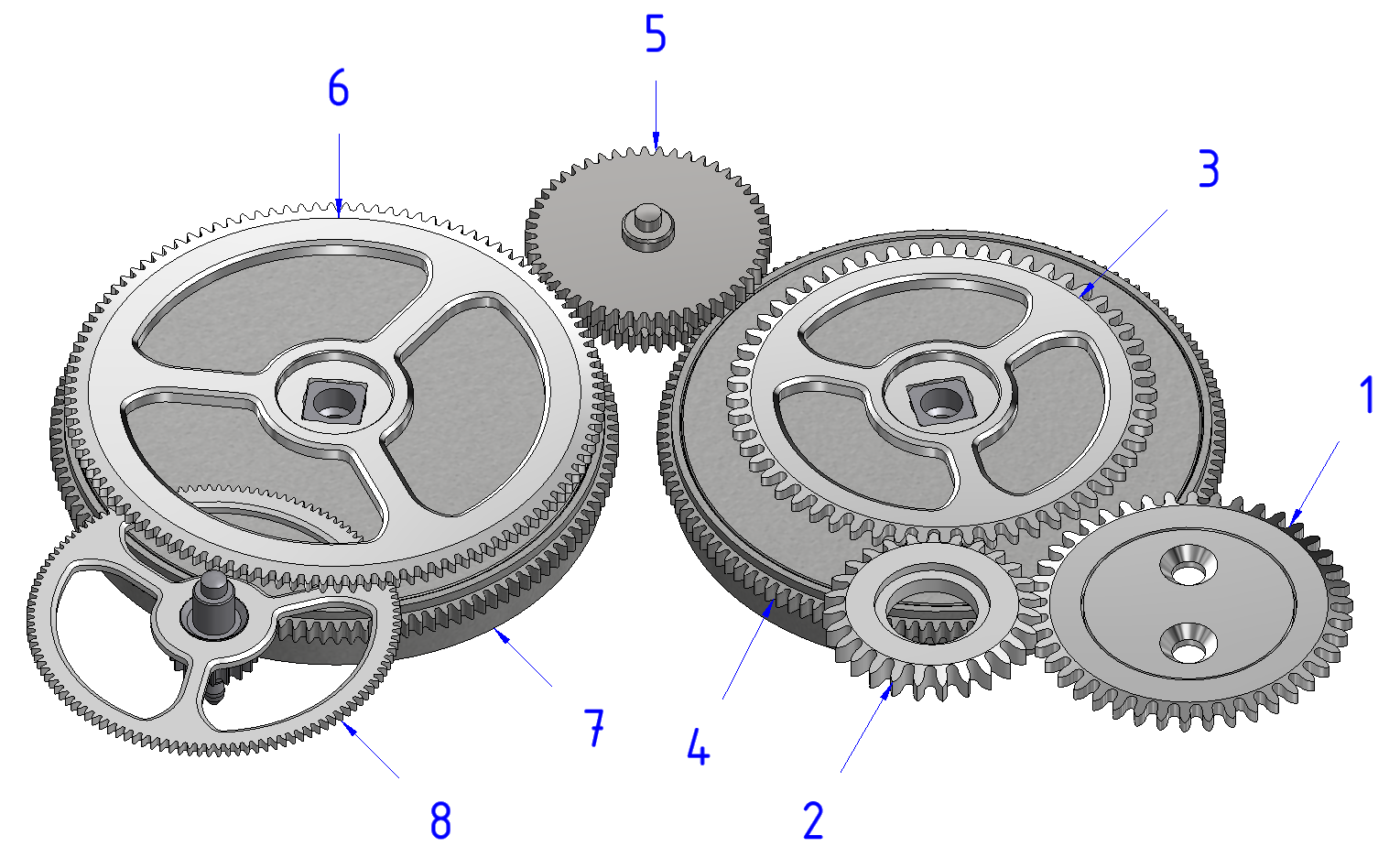

The first barrel (7) is the only one which drives the gear train (8). When its torque falls below a certain percentage of that of the second barrel (4), the latter compensates for the lack of torque of the first barrel (7). During winding, the ratchet (3) is driven by the reversing gear (2) which transmits the rotation of the upper crown wheel (1). The ratchet wheel 3 winds the second barrel (4) and when its torque is sufficient, the latter rotates and drives the intermediate wheel (5). This wheel (5) rotates the ratchet (6) and thus makes it possible to wind the two barrels (7 and 4) until they are fully wound.

Images of the case before assembly

Diverse images of the finished Nebula

To learn more about Arnold & Son www.arnoldandson.com