The Reason

A classically designed, 8 day power-reserve manual wound time-piece.

Functions

Hours, minutes, small seconds, date, power reserve indicator for 192 hours.

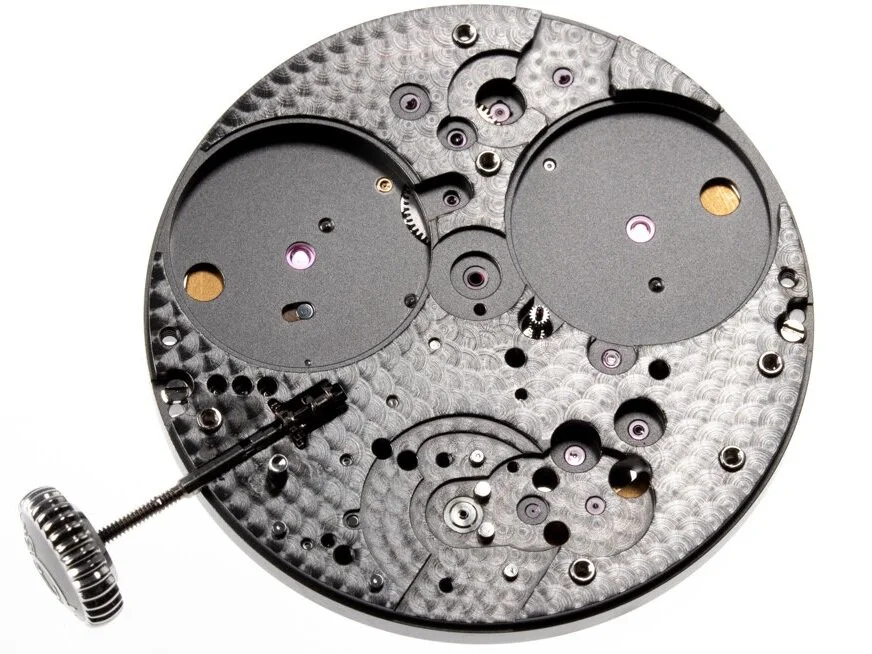

Through the rear sapphire the semi-skeletonised movement is viewed cutting away the bridges to reveal the two barrels and going train.

Technical Specifications

Movement calibre A&S1016, thickness 4.7 mm, diameter 33 mm. Number of Jewels 33. Power reserve 192 hours. Frequency 3Hz, (21,600 VPH). Steel case, 43 mm in diameter and water resistant to 3 atmospheres (30 m). Sapphire crystals in bezel and case back.

Please move the cursor across the image below, (or by finger on a smart phone), to rotate the watch.

With the exception of the flat surfaces on the shoulders that are straight grained manually, the case surfaces are polished.

Partial view through the case back. The majority of the wheels within the calibre have 3 arms, the largest have polished angles to associate to the diamond cut/polished bridge angling.

The two largest wheels in view are the ratchet wheels for the barrels that contain the mainsprings powering the movement. They are linked through the gears at the top of the image, both used to wind the two barrels simultaneously and transfer power to the train as the watch unwinds driving the going train, escapement and balance.

The case back is fixed to the centre by 6 stainless steel screws. A silicon seal is sandwiched on the inner surface of the case back, pushing against the case centre to assure the case back remains water-resistant.

The shoulders are mechanically attached to the case centre slotted in place and fixed with 2 screws through each one. The system is used to allow for the complex and flat machining and finishing of the step on the outside of the shoulder design.

The 3/4 form of the main bridge is reminiscent of the early English movement design.

The Geneva stripe decoration radiates from the balance wheel centre out, over the movement bridges.

Where as the case back is held in place by 6 screws, the bezel is held in place by a compression fit. The movement and dial are removed through the front of the watch requiring the bezel to be removed first. To remove the bezel there is a small angle set at 12 o’clock between the bezel in the case centre that allows a specialised blade to lever the bezel free.

The watchmaker removing the bezel.

The slight angle at 12 o’clock in the case centre allows the bezel to be levered off.

The movement, dial and hands assembly removed from the case.

The assembly held in a tailored movement holder.

The hands removed from the dial and movement.

Under the black lacquered surface of the dial is an engine turned decoration.

Printing of names, motifs, numbers and indexes is a particular science. Keeping the integrity of a design whilst repeatedly re-printing the brand name multiple times on a single dial to produce a domed effect is not an obvious operation, here it is well executed to create volume in the aesthetic of “Arnold & Son”.

The dial removed from the movement revealing the date ring and the spotted (pearlage) finish of the main-plate and central cover plate.

The base material of the dial is brass and the indexes are riveted in place from the back of the dial, after the lacquer and printing has been executed.

The dial is held in place by two screw head plugs that are pushed into the main-plate and have eccentric sides that when turned lock the dial feet in place. One can be viewed below, set into the dark grey main-plate, below the bridges.

The finished colour of the bridges is made using rhodium, the grey main-plate is rhutanium plated. The bridges and main-plate are made from German silver (Maillechort).

The hands, like the indexes are machined from brass, faceted and flat surfaces mirror finished then rhodium plated.

Engraved around the 3/4 plate bridge is ADJUSTED TO FIVE (5) POSITIONS. This signifies the number of different positions the watch has been tested in, to assure a specific accuracy of the watch when it is worn.

The blued screws are made from steel and heat treated to achieve the colour.

The red synthetic jewels are pushed into gold chatons (bushes) that are in turn pushed into the bridge and locked in place by blued screws.

Gold chatons were used in early high-end pocket watches, where the jewels were riveted into them before being held in place by 2 or 3 screws.

The blued screwed in the centre of the image holds in place the click that prevents the ratchet wheel from unwinding when the watch is wound up.

When the ratchet wheel turns clockwise the click is pushed out of the way to allow it to turn. When the ratchet wheel turns anti-clockwise under the force of the mainspring the click armed by a small spring to its left causes it to engage with the ratchet wheel teeth blocking it from turning.

An exploded view of the rear of the movement.

Click, to see full image.

The balance wheel, and cock assembly removed from the movement.

The balance cock is located in place by two steady pins set into the main-plate that slide into holes machined into the underside of the balance cock.

The balance cock is locked onto the main-plate by a blued screw.

The top and bottom balance pivots are held in place, pivoting in Incabloc shock protection.

With the balance removed the Swiss Anchor Escapement is partially viewed, held in place by the horse-shoe shaped bridge.

Under the horse-shoe shaped bridge, the tail end of the Swiss Anchor is viewed which engages with the balance wheel impulse jewel, driving the balance wheel.

The two large banking pins either side of the Swiss Anchor tail limit the movement of the anchor.

The Swiss Anchor and its bridge removed.

The locating steady pins for the anchor bridge are set into the main-plate as with the other bridges. In earlier wristwatch calibres the steady pins were set into the bridges.

The train bridge holding in place the escape, 4th and 3rd wheels removed.

The escape wheel is made from steel, its teeth acting on the Swiss Anchor pallet jewels. All of the wheels before the escape wheel are made from brass, then decorated, plated and lastly having the teeth cut to ensure the brass metal has direct contact onto the polished steel pinions.

The escape wheel and 4th wheel removed. The 4th has an extended pivot upon which the small seconds hand sits.

The 3rd wheel can not be dismantled until the main 3/4 bridge is removed.

The principle 3/4 bridge removed revealing the complete barrels, intermediate train and going train.

Historically a basic difference between Swiss and English movement design lies in the form of the bridges. English were often made with a single large bridge (known as a 3/4 plate). Swiss and French (Lepine) calibre’s used multiple bridges and cocks (also know as bars).

The barrel assemblies.

Assembled. Some of the wheels are hidden under the main-plate when the movement is assembled.

Exploded, high-lighting the complexity of the construction.

Recto-verso of the 3/4 bridge.

The 1016 is the Arnold & Son calibre reference.

The large pinion meshes with the winding system. The small one is part of the train that transmits power between the barrels.

The fully dismantled main-plate

Barrels and wheels from the going train.

The dial side of the movement with the central cover plate removed, revealing part of the 8 days power reserve mechanism, the rapid date change and normal date change systems.

The size of the numbers on the date ring are designed associated to the their form and quantity, to optimise readability through the dial aperture.

Part of the 8 days power-reserve mechanism.

The rapid change date system.

The date change system and indexing pawl.

Click, to see full image.

Summary

Increasing the size of the calibre to hold 2 large barrels for the extended power reserve, held under a 3/4 train bridge, omitting the need for a movement ring, results in a Swiss/English fusion timepiece.

Although entirely Swiss made and modern in interpretation, there remain elements in design from the movement through to the case and dial that link to classical English watchmaking but re-visited, re-thought, and executed.

To learn more about Arnold & Son