The assembly of the Francastel music box

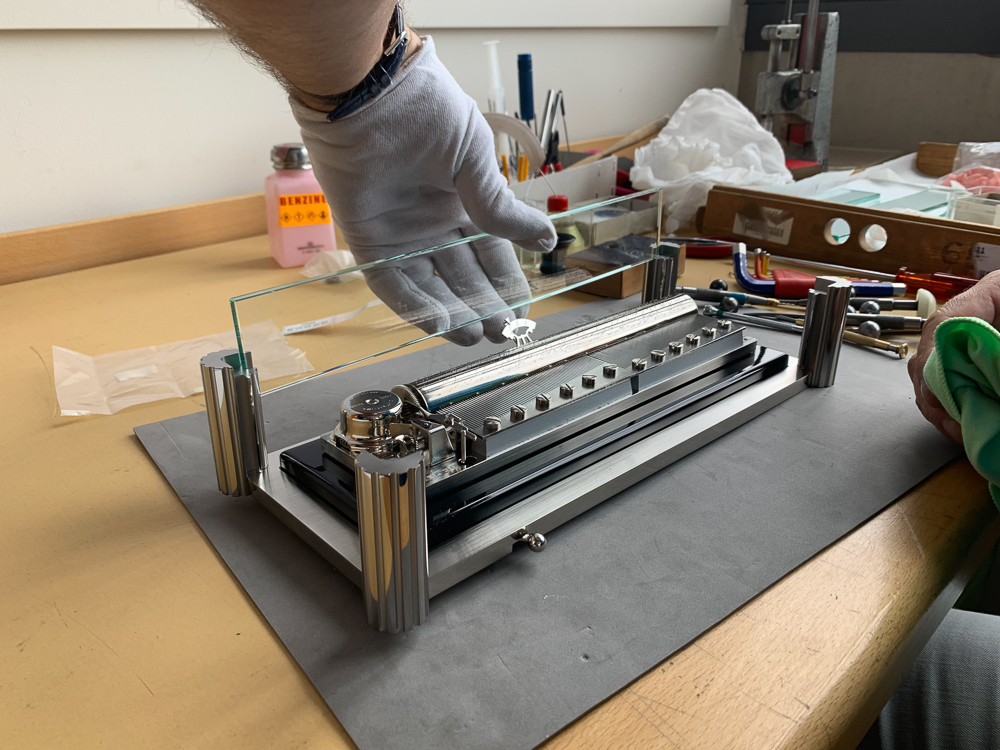

The ‘Francastel’ has over 1’200 pins placed on the cylinder and two 72-note combs. 3 melodies are played, approximately 36 seconds per tune. It has a 16-minute power reserve.

The main-plate of the mechanism is made from a heavy plate of brass which is CNC machined then finished with a large horizontal Geneva stripe decoration.

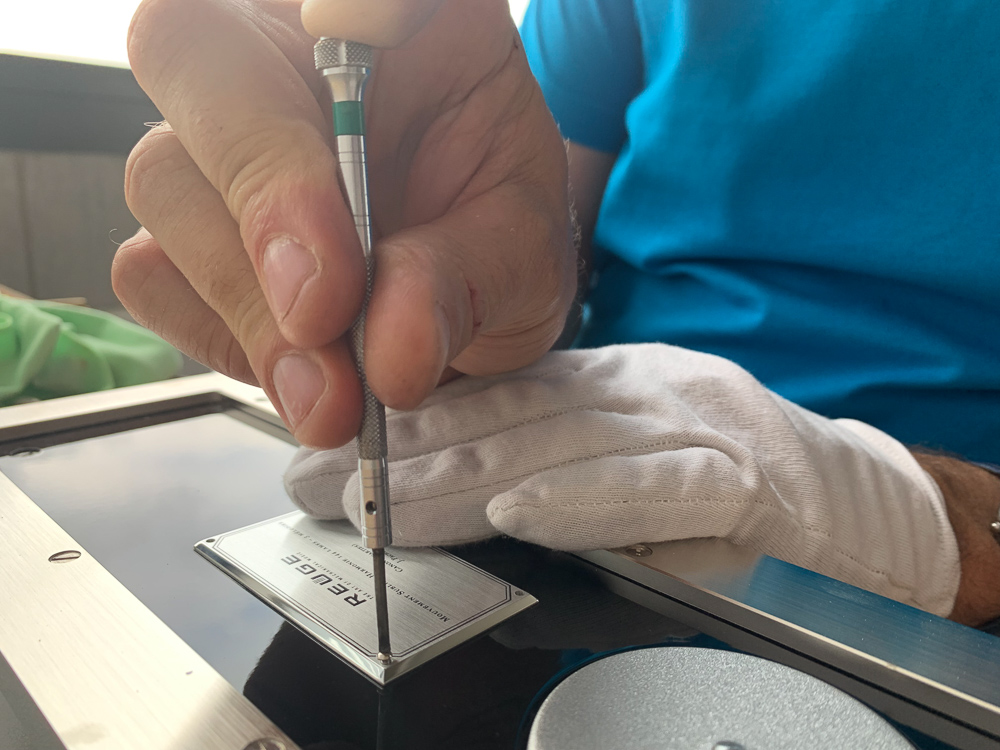

Once the components are ready for assembly they are collected into kits then given to a technician to assemble.

To assemble the music box, the main-plate is placed on a wooden box of the same type as was used when music boxes were first produced.

The driving and ratchet wheel assembly with contrate (90 degree) teeth which is driven by the barrel and in turn drives the spindle which turns the cylinder.

The upper bridge for the driving and ratchet wheel assembly.

The contrate teeth which mesh with the spindle driving the cylinder. Situated above the teeth is the hole in which the spindle pivots.

The assembled cylinder and spindle. The small pinion next to the end pivot meshes with the contrate (90 degree) teeth.

The spindle pivot being greased then placed into position.

The bridge is made from a flat sheet of brass, pressed multiple times to produced the final drum form.

On the apposing end of the cylinder a conical spring is added which pushes it towards the barrel end, removing all end shake and allowing the selection device for the different melodies to be held in place.

Synthetic greases are applied to all pivoting surfaces.

The second end-bridge is added that carries the cylinder spindle pivot.

The mechanism is then turned upside down and held in the steel support which has been sitting at the back of the assembly box.

The brass wheel is pushed onto the arbour of the contrate wheel.

The first pinion with a threaded axel will eventually carry the winding key. The pinion meshes in turn with the intermediate pinion which drives the wheel pushed on to the barrel arbour that subsequently winds the mainspring.

The bridge holding the above two pinions in place.

The barrel being assembled.

The mainspring inserted.

The grease added.

The barrel arbor/drive wheel inserted.

The barrel cover plate added.

The barrel added to the underside of the main-plate.

Next, the mechanism is turned over and the air-brake added.

The assembled air brake.

Worm pinion driving the air-brake.

The brake assembly is placed in position then screwed gently in place.

The screw holes for the assembly are larger than the diameter of the screw threads. This allows the technician to adjust the penetration of the air-brake pinion assembly and the wheel fixed to the cylinder spindle. If it is too tight, the mechanism will bind and stop; too loose, power is lost in the transmission. The technician feels the required play between the pinion and wheel then tightens the screws.

The selection lever added which indexes the selection device/cam to change between the three melodies.

The dial mechanism that shows which melody is being played.

Finally the combs are then added to the mechanism, adjusted to be aligned with the pins on the cylinder and tightened down solidly to assure maximum resonance of each note.

Aligning the comb with the cylinder.

This video is over seven minutes in length with out editing. ‘Remy’ the technician filmed has been with Reuge for over 35 years (2019).

Assembling the mechanism in the music box.

Diverse angles of the finished box, please click to see the full image

Summary

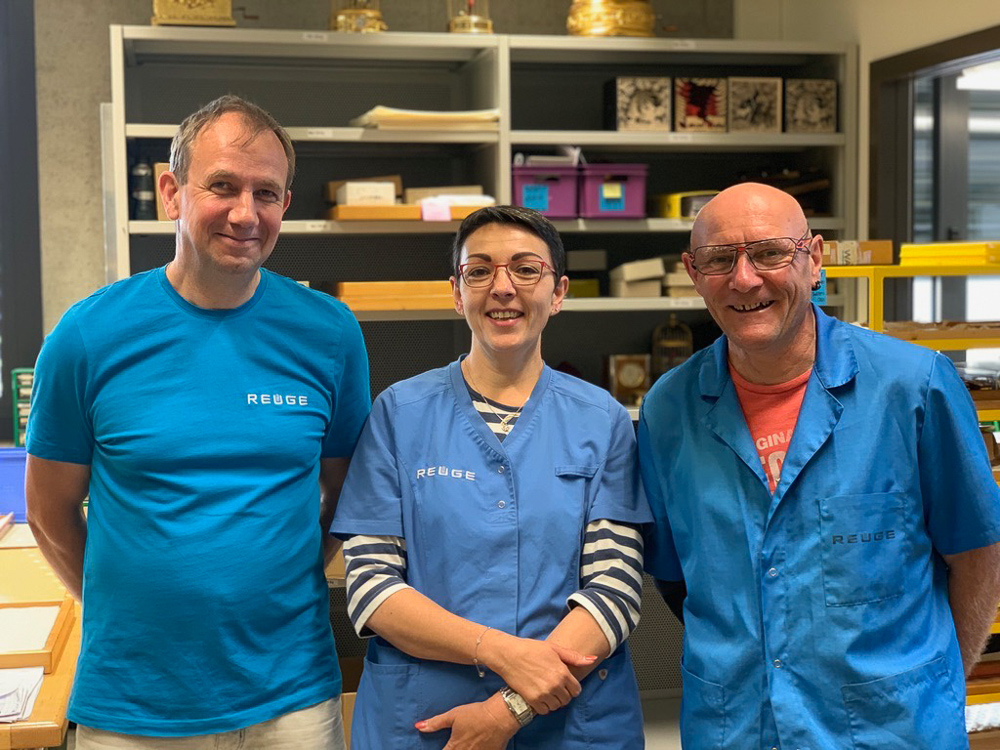

Three days were spent at the REUGE factory, in this time we witnessed every aspect of the manufacture of the music boxes. The result can only be described as a modern mechanical marvel. The skill of the team making, assembling, adjusting, filing, tuning, making minute adjustments to find the perfect tune. There is a vast chasm of difference between watchmaking and making music boxes. In the horological world, there are hundreds of brands and many manufacturers, within the special world of music boxes, REUGE is one of the few, if not the only one left producing music boxes of this calibre. The experience felt when activating and listening to the boxes is a combination of timeless; echoing to another period in time, and bordering on therapeutic.

(2019) Bertrand, Sylvie and Rémy, between the three people they share 85 years of experience assembling music boxes at Reuge.

The Three Melodies