The Reason

The first example of watchmaking from Japan to be presented on the platform.

The original deconstruction of this watch was made in 2017 of a piece that was produced several years earlier and well used.

Since the production of this watch, Seiko has altered the branding design on the dial. Although the body of the deconstruction shown here remains the same, the first image shown below represents the new design of the dial.

(The new dial design, 2019)

The Original Deconstruction

(Revised version)

The case back is held in place by being screwed tight with a 6 fingered key. The glass in the centre is made from sapphire.

The case back removed, followed by the rotor

Unlike the majority of Swiss calibres which have the rotor ball races screwed in place by either one or three screws; here the ball race has a steel central ring with an internal thread. This screws onto a threaded tube set into the main train bridge. The system is simple and strong and reduces the number of parts required. To secure the rotor a three-pronged tool is used to loosen (or tighten the assembly).

An inclined view of the dial, movement with hands removed from the case.

Flat polished, heavily angled daufine hands.

The dial removed recto-verso, showing the riveted indexes and name plaques.

The solidly constructed stainless steel case.

Glass material sapphire, treated with anti-reflective coating on the inside only.

Etched on the inside of the sapphire is the Grand Seiko logo and name.

The crown tube with cross key way.

The cross key way associates to the tool used to screw the tube in place

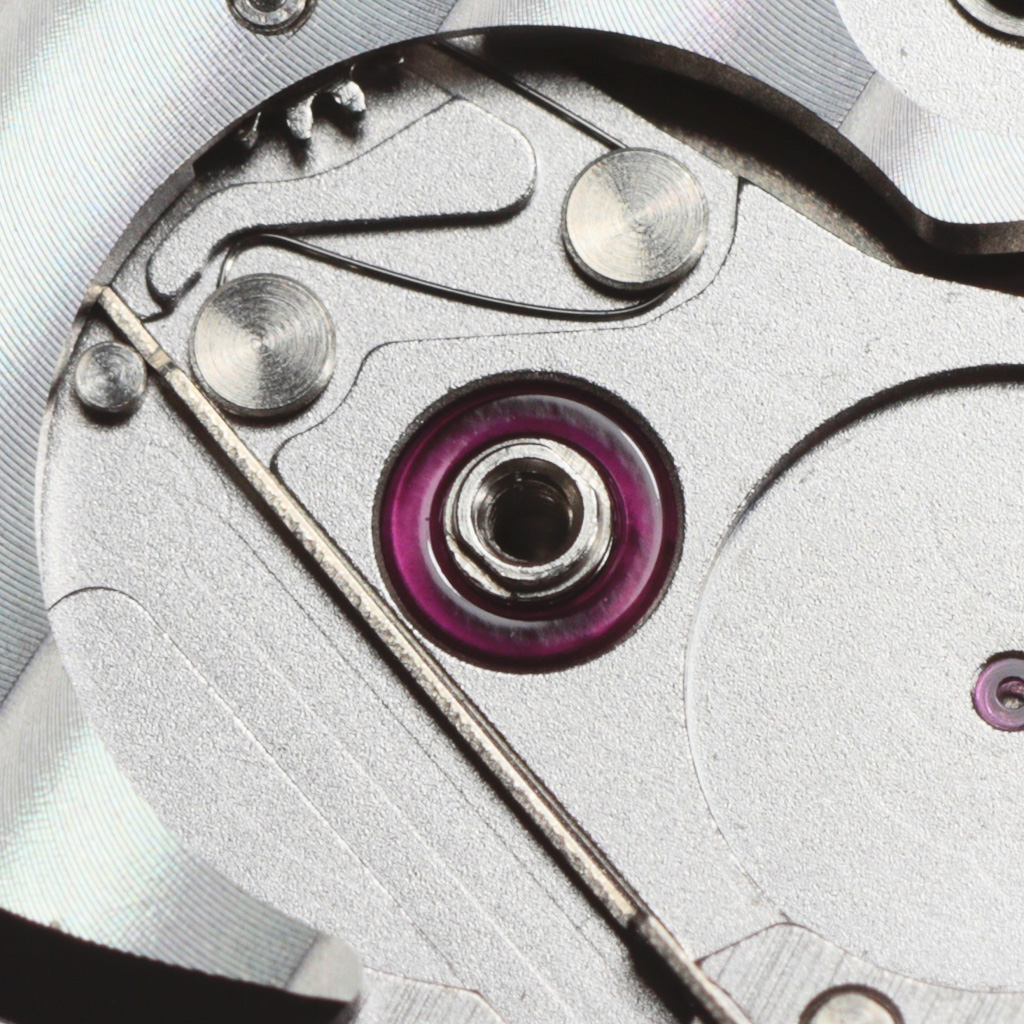

View of the movement from under the dial.

On nearly all winding stems since the 1940's there is a thread which can be adapted in length to accommodate the length of the stem in relation to the thickness of the case. On this stem, there is an alternative approach with a simple rod form with two milled flattened sides driven into a corresponding shaped crown tube. Also on the crown tube, there are two synthetic seals to render the winding crown water resistant inside of the case tube.

Power reserve 55 hours Vibrations 36,000 VPH Jewels x37

The balance spring. Grand Seiko uses a new generation of Spron alloys. Spron 610 alloy was developed over a five year period. Compared with previous alloys, Spron 610 had twice the impact resistance, and a magnetic resistance more than three times higher than previous versions.

MEMS technology developed in-house from semiconductor manufacturing, the escape wheel and pallet fork used in Caliber 9S85 are made with a precision of one thousandth of a millimeter. MEMS (Micro Electro Mechanical System) is a technology that allows components to be lighter, smoother and, in the case of the escape wheel a more intricate design. The new design of the escape wheel featured oil reservoirs at the end of each gear tooth, improving the retention of oil. The same technique is executed in Switzerland by companies like Mimotec.

Summary

The overall construction of both the movement and the case is congruent with the goal of a strong and precise timekeeper designed for longevity. A solid stainless steel, two-piece case with one of the strongest case tubes ever machined. The fully jewelled calibre has all wheels pivoting in rubies. The resulting calibre combines vintage solidity in construction with, modern manufacturing techniques and alloys effectively.

To learn more about Grand Seiko