The Naked Watchmaker YouTube channel: Film presenting André restoring an antique pully system

Examples of antique watchmaking tools restored by André Léchot

Reviewed December 2020

Mr André Léchot has spent the last 40 years restoring, in his spare time antique and vintage watchmaking tools that may otherwise have been neglected or destroyed. His goal was and remains the preservation of this part of horological history.

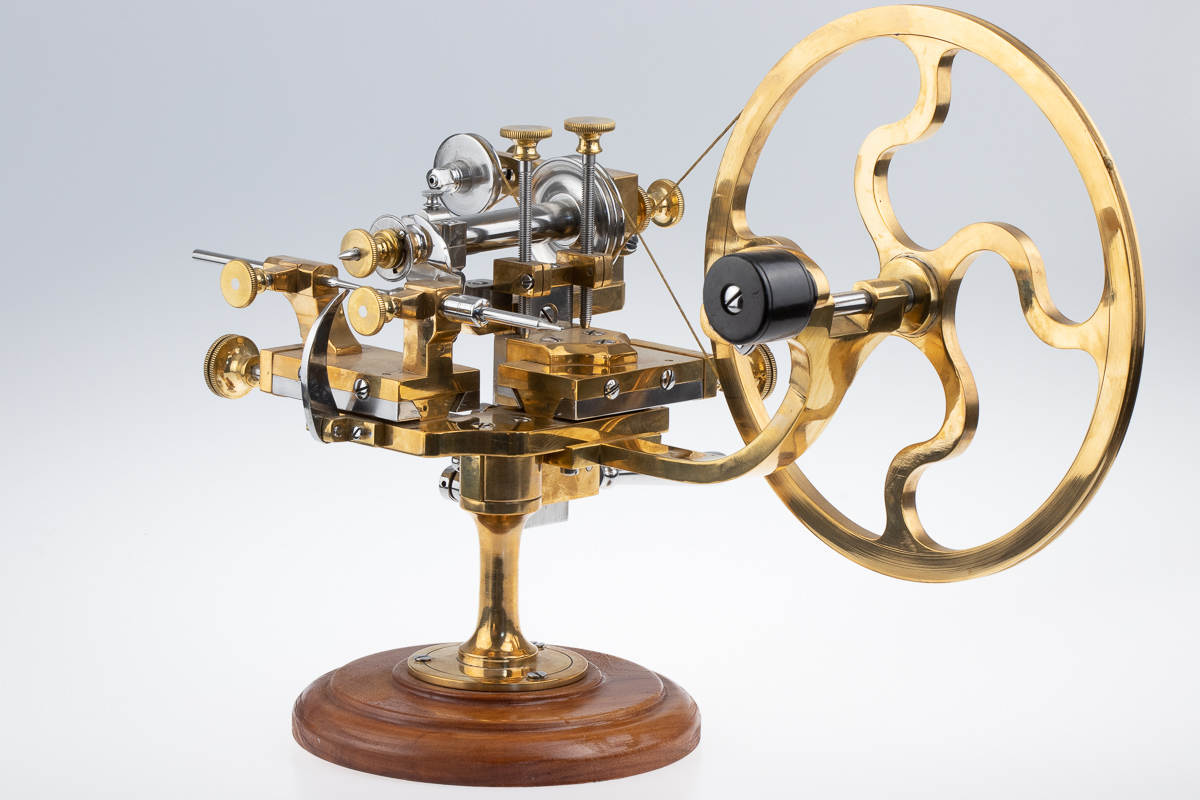

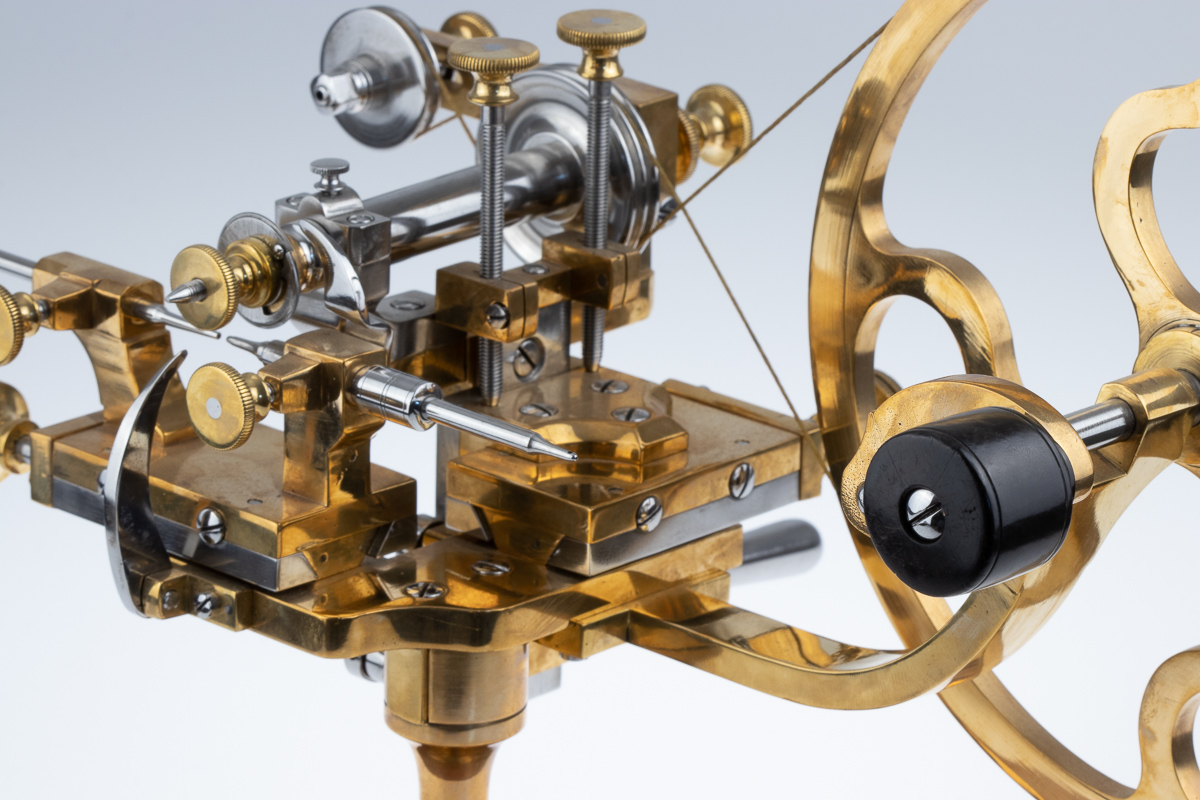

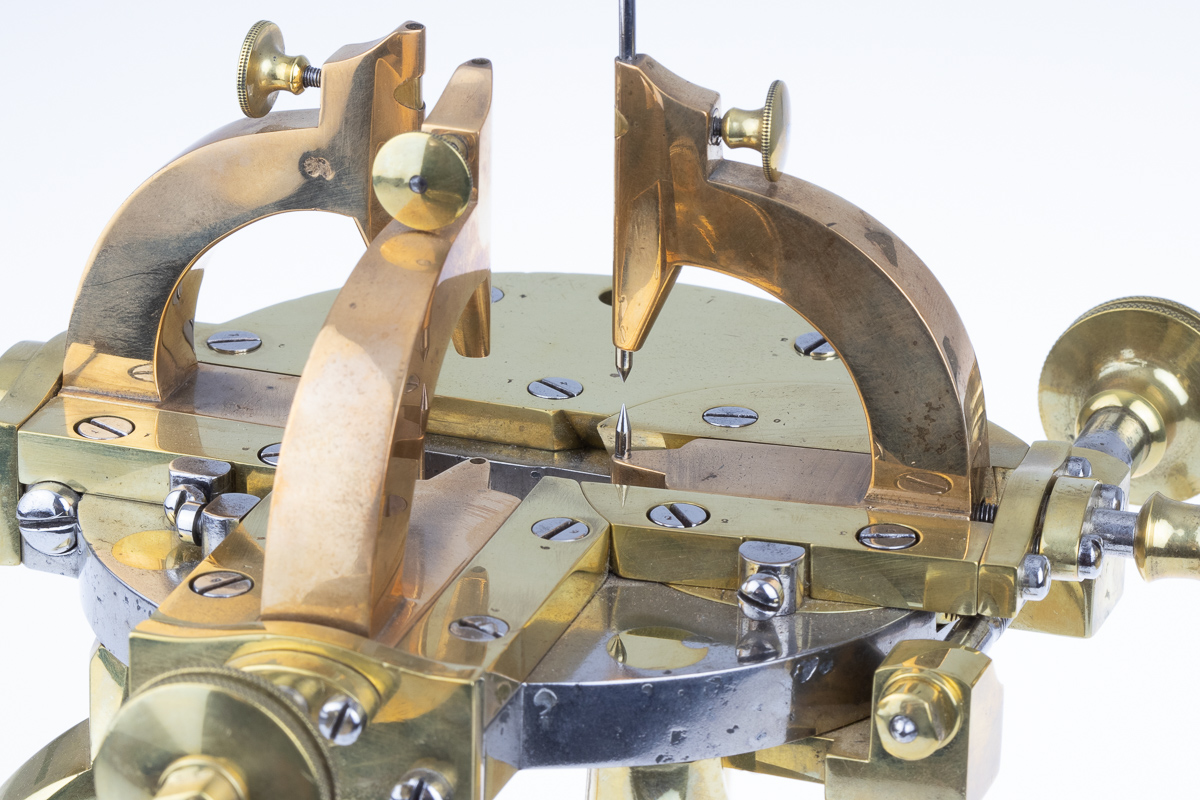

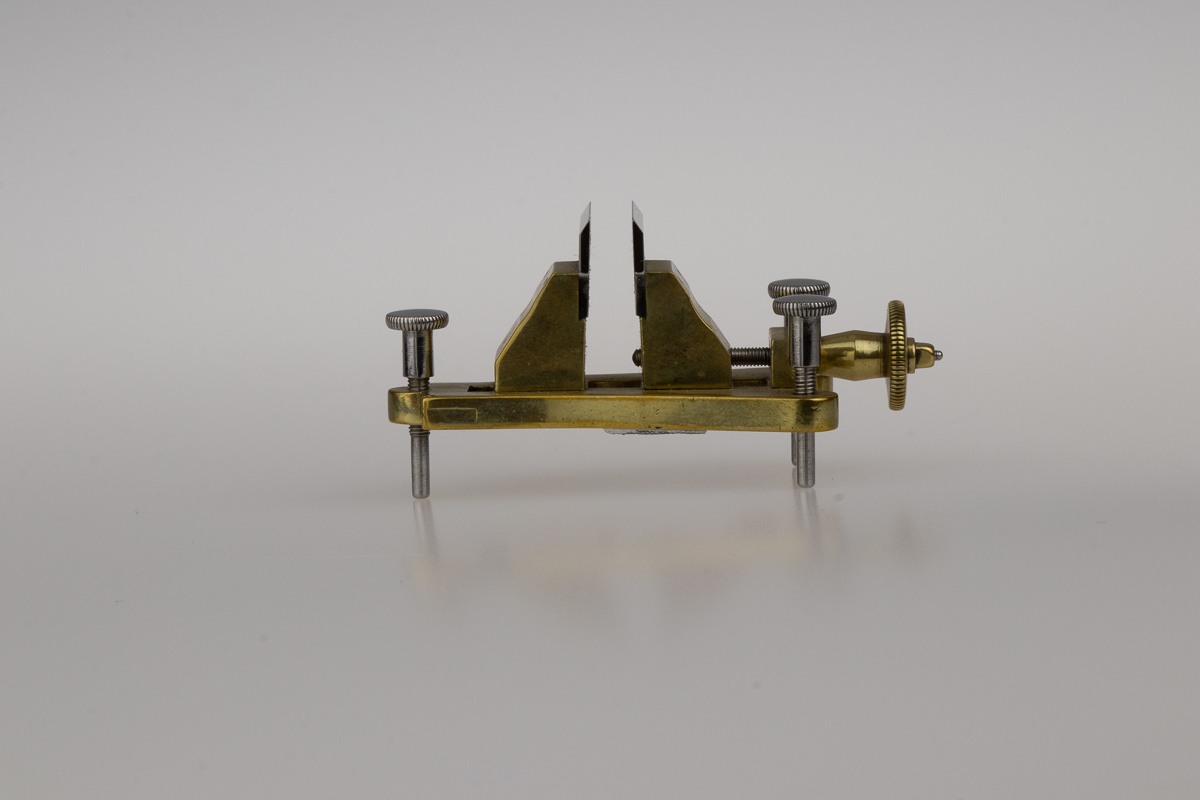

A topping tool

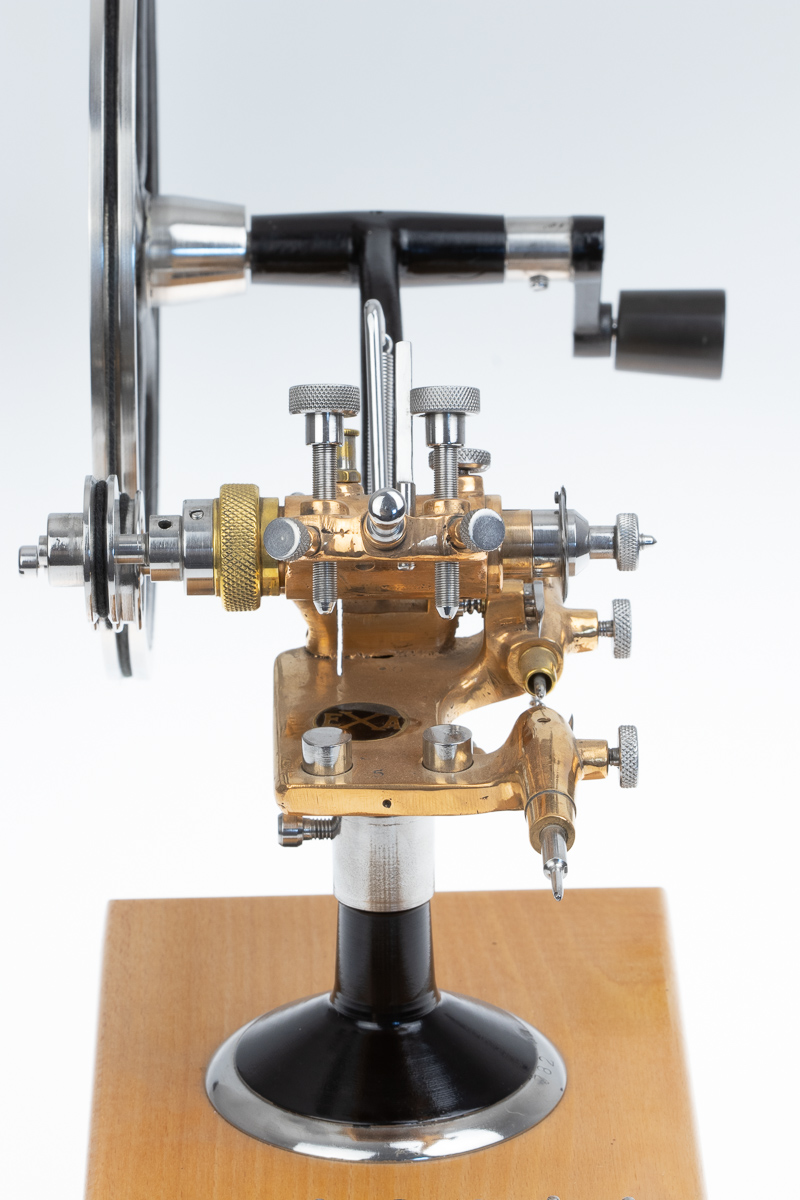

Topping tools were made to alter (or develop) the profile of the teeth on wheels. Rarely used today outside of restoration of early pocket watches or vintage wristwatches.

The steel disc in the centre is the cutter that files the form of the teeth of the wheel. It is ‘split’ and adjusted, with the lateral steel screw set into the disc, to be able to index the next tooth.

The two long screws adjust the height of the disc in penetration with the teeth which are being modified, twice for security.

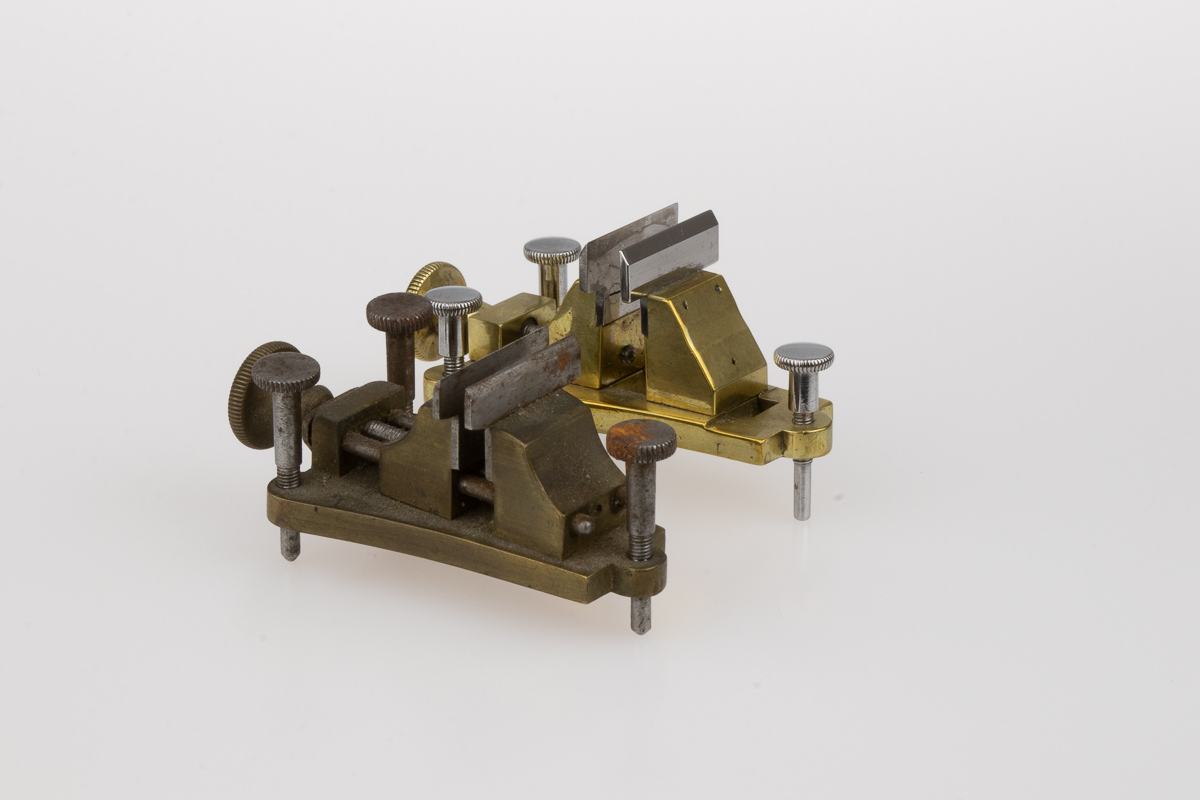

A second topping tool of similar period fixed to its original box, containing multiple cutters and accessories. Each cutter would cut or refine a different profile.

An unusual topping tool with straight arms. (The base is not original)

Made from brass, steel and bronze.

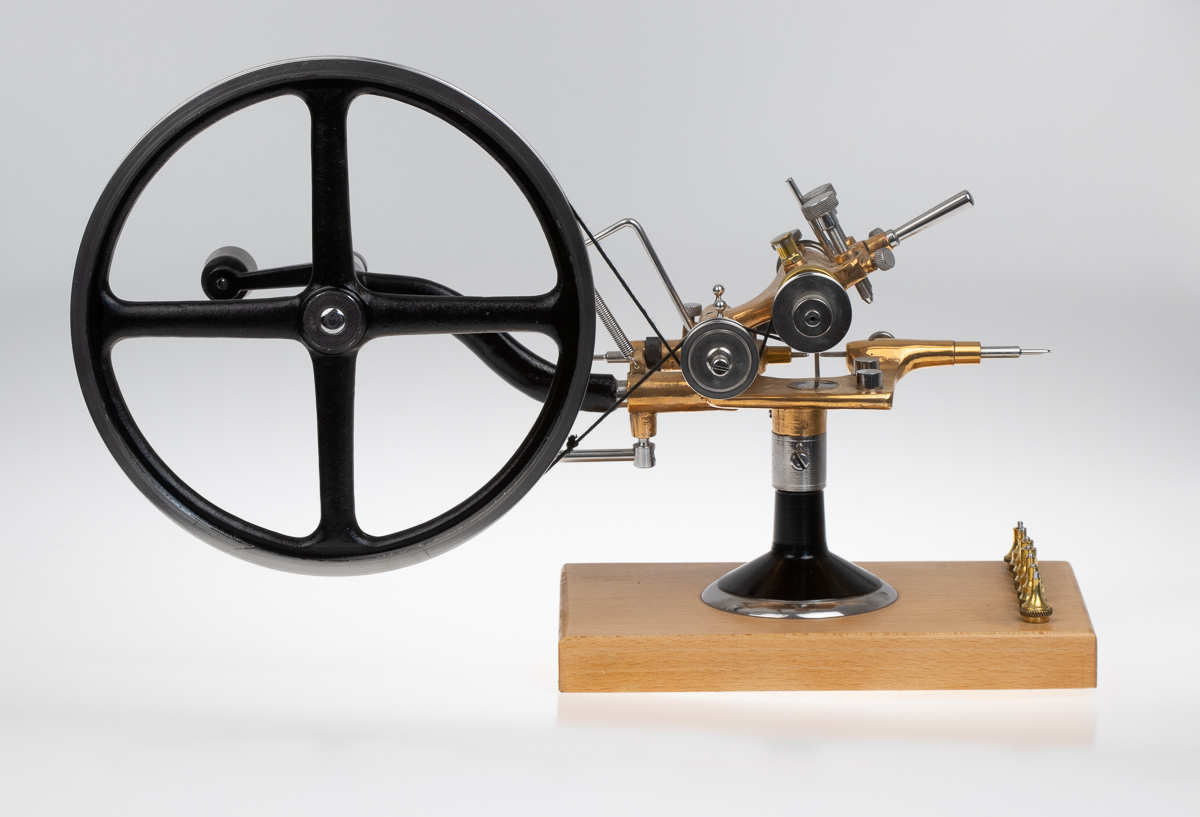

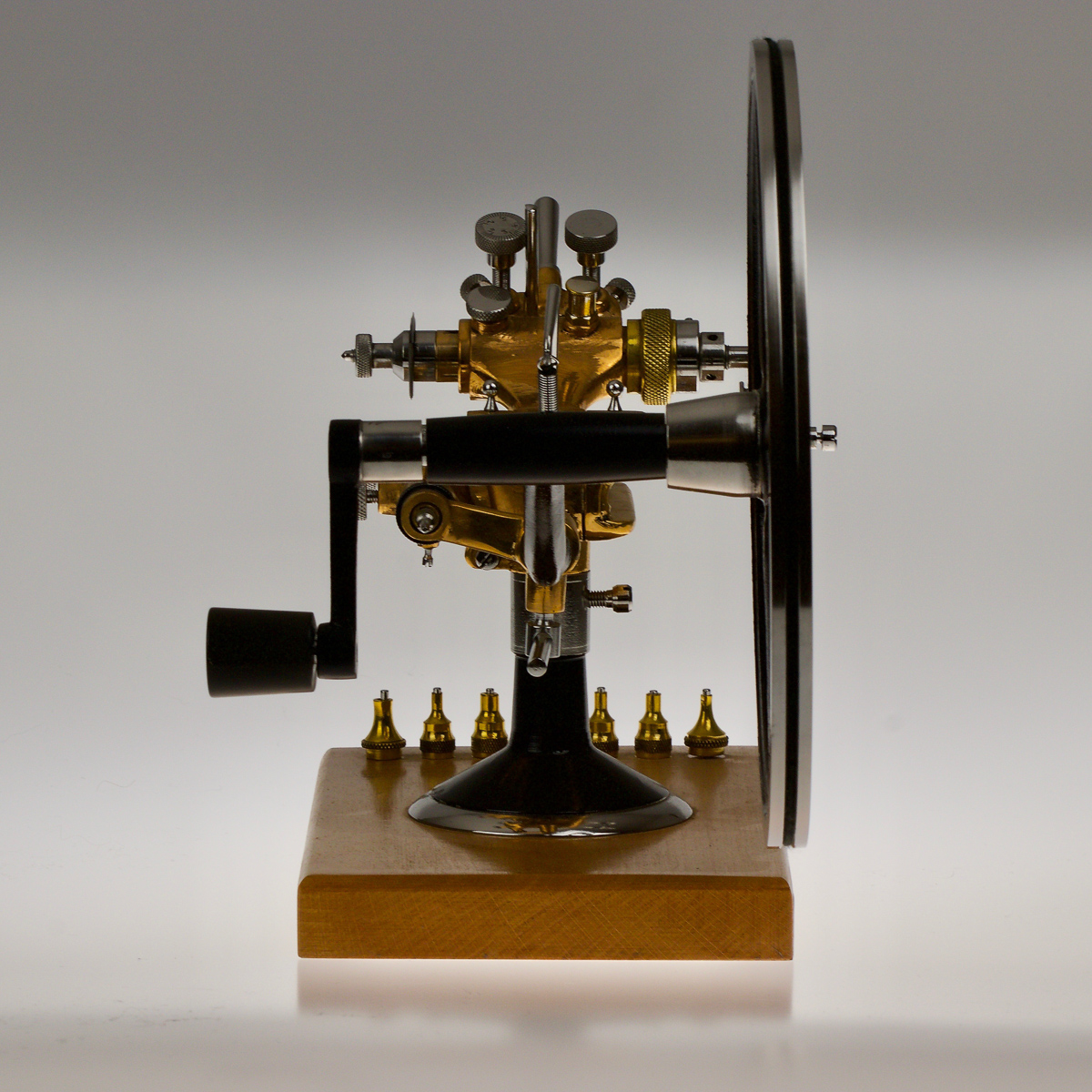

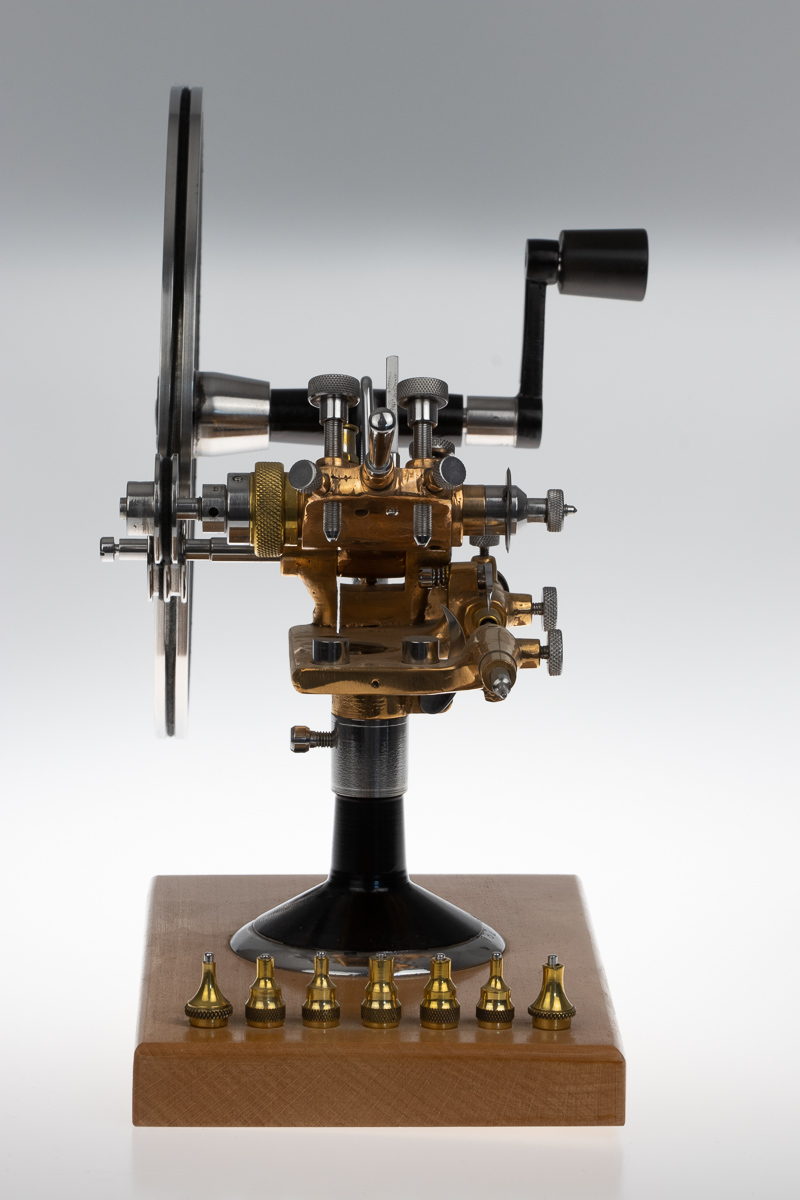

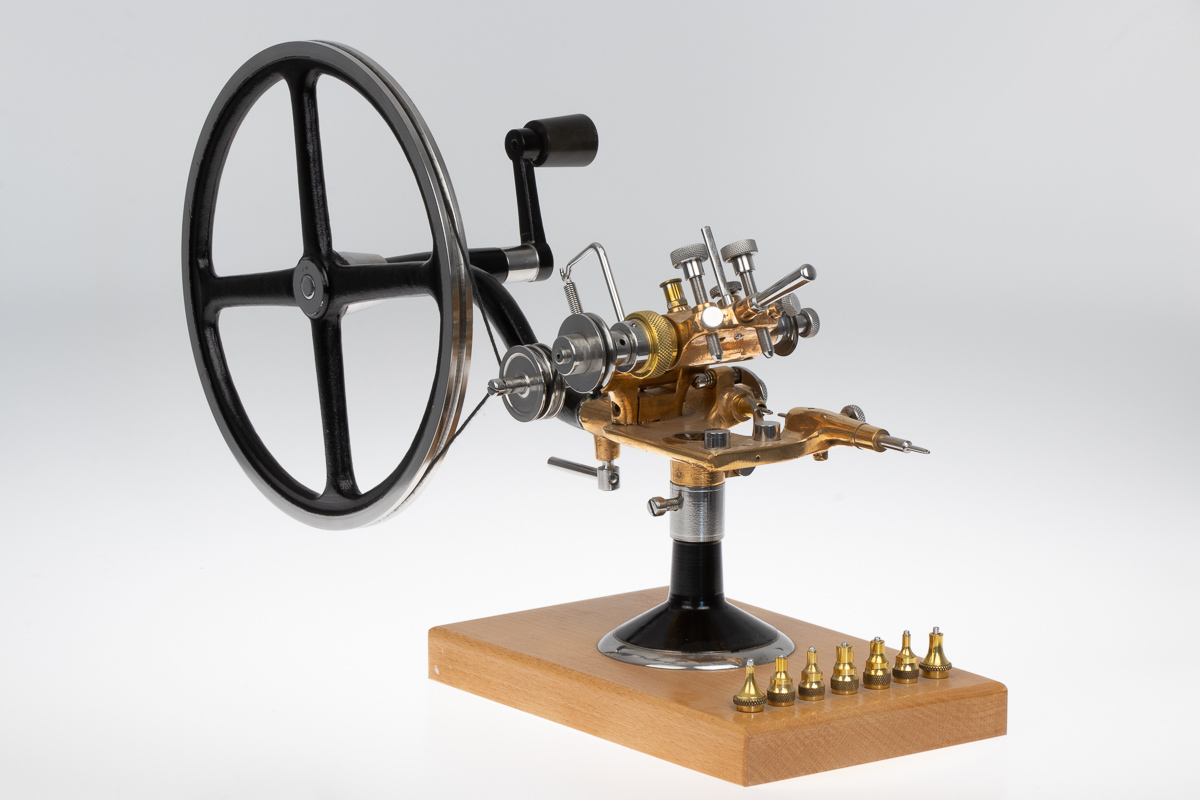

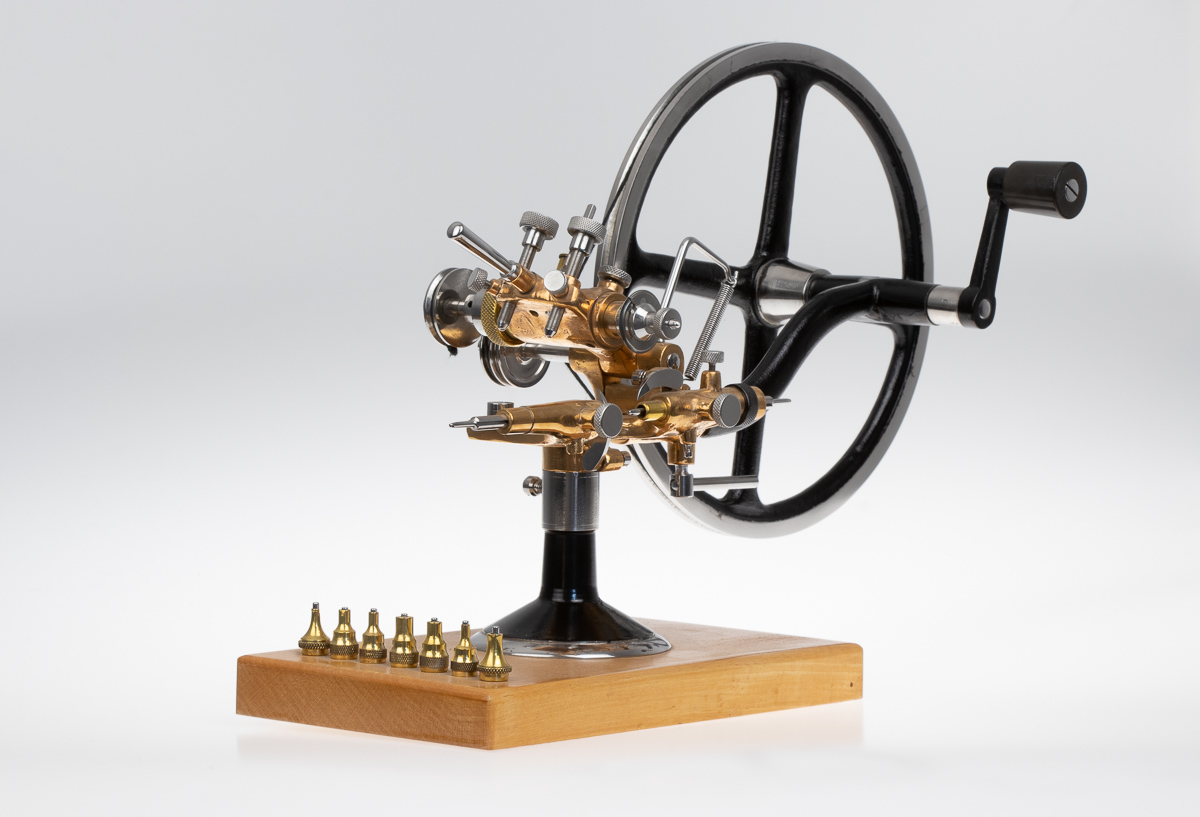

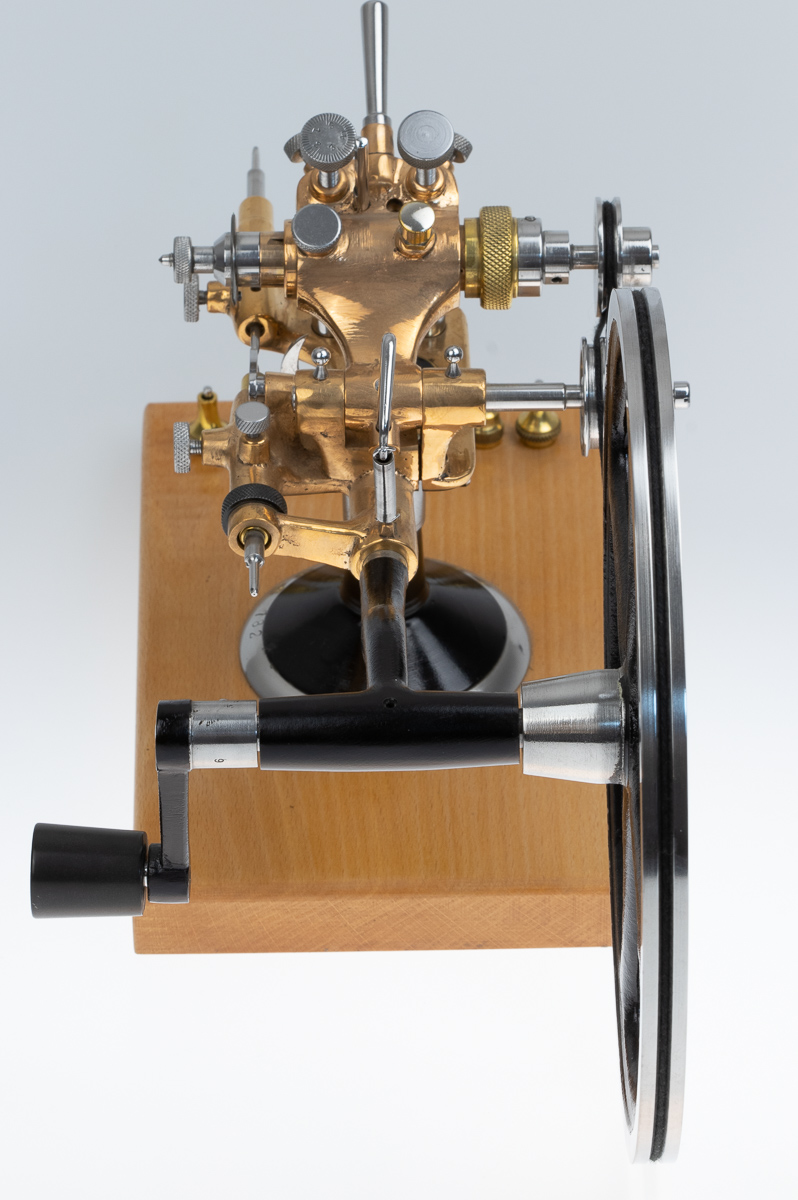

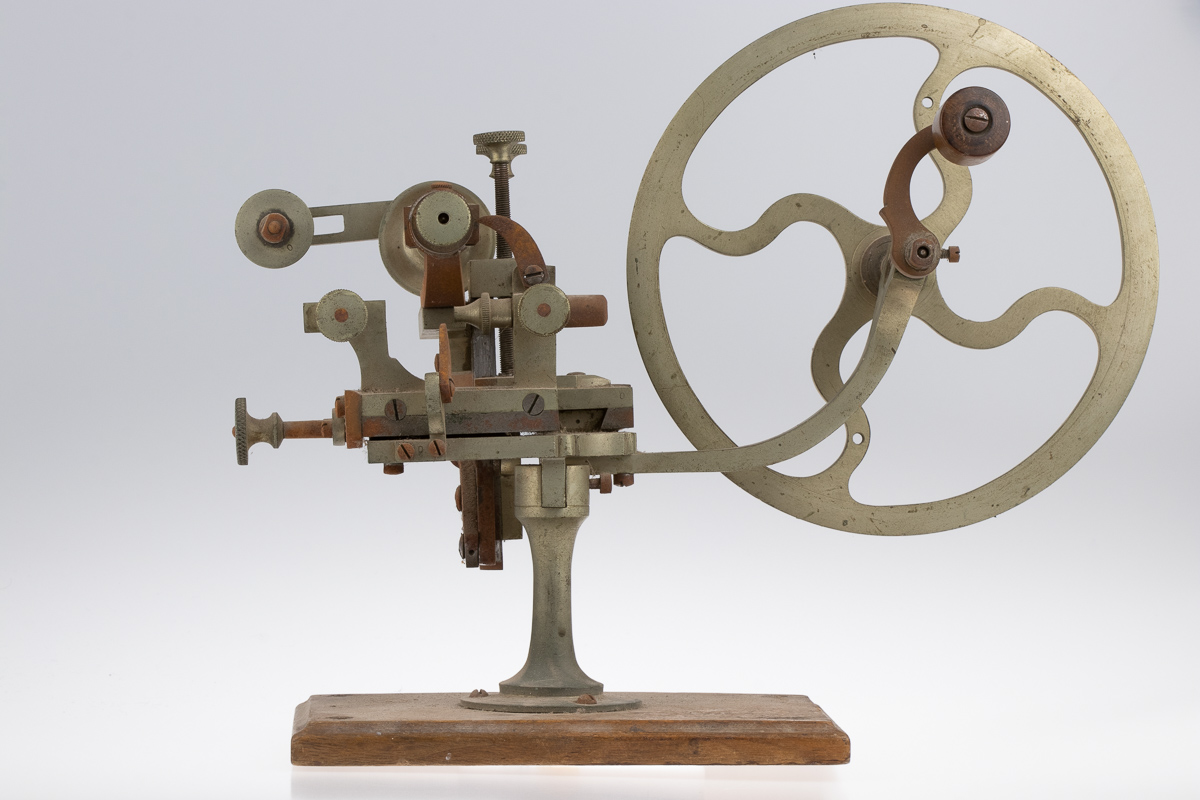

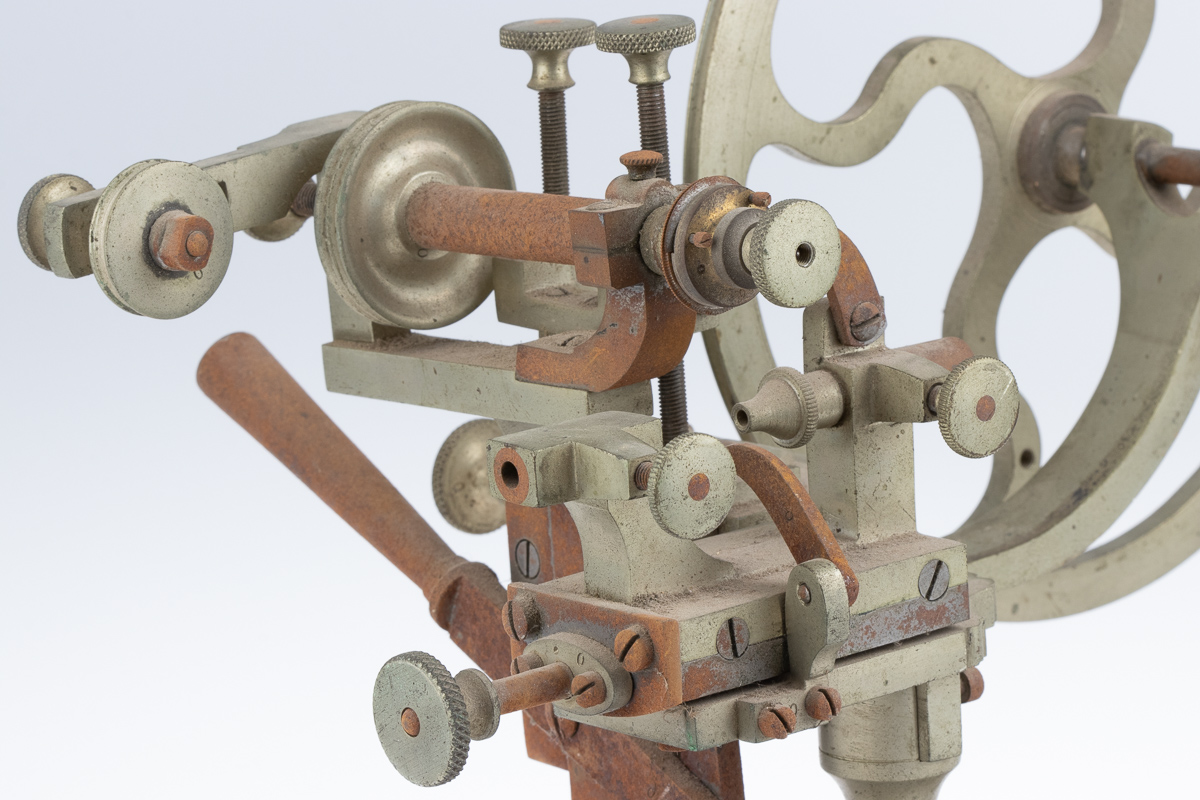

A topping tool from the 1920’s. Predominantly made from bronze, with a cast iron driving wheel.

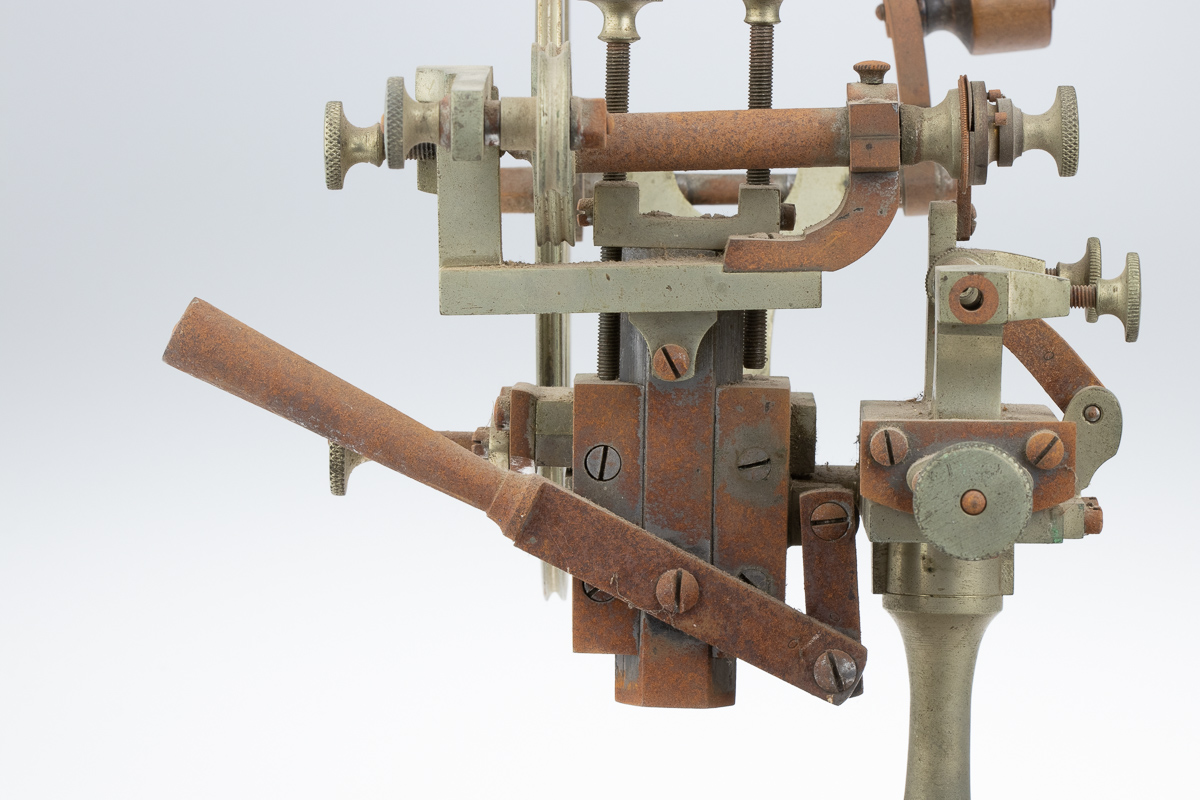

The images below show an example of a topping tool prior to being restored. Often Mr Léchot receives these tools in this condition or far worse. The first challenge in restoration is to dismantle tools which are heavily rusted.

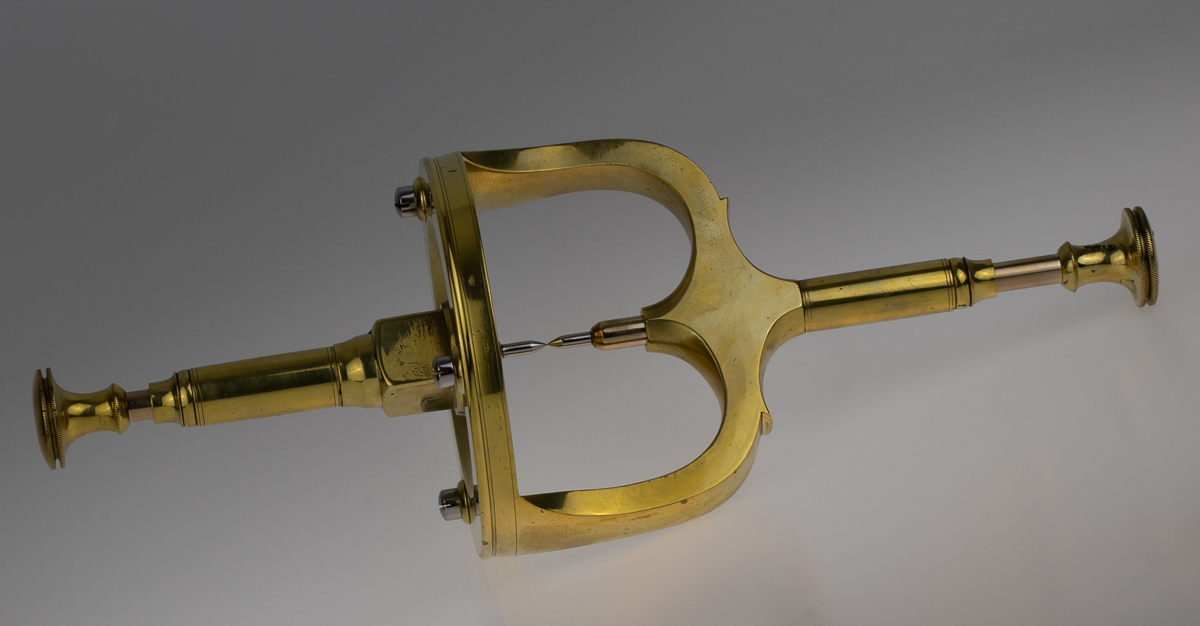

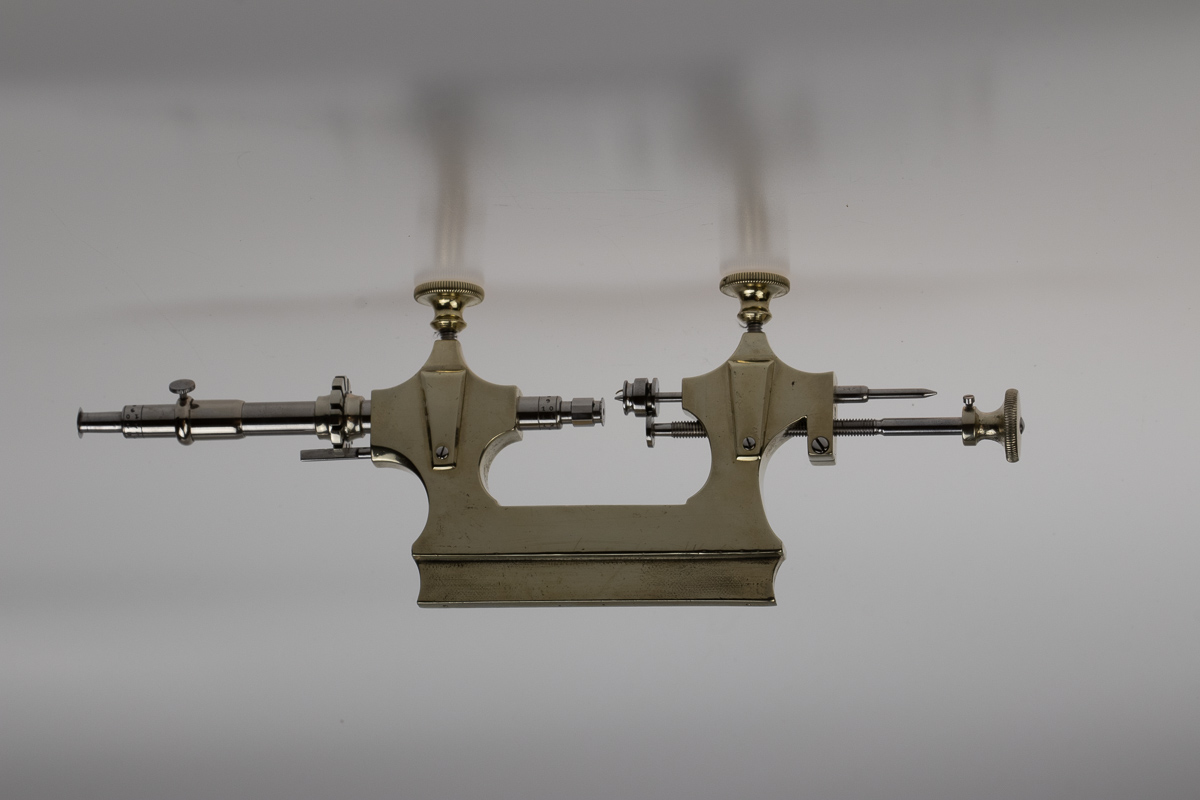

A depthing tool

Two complete mobiles (wheel and pinion) are placed between the spindles and the penetration between wheel and pinion adjusted manually. Once correct the end of the spindles scribed the correct arc distance for the positioning of the two mobiles on the main-plate.

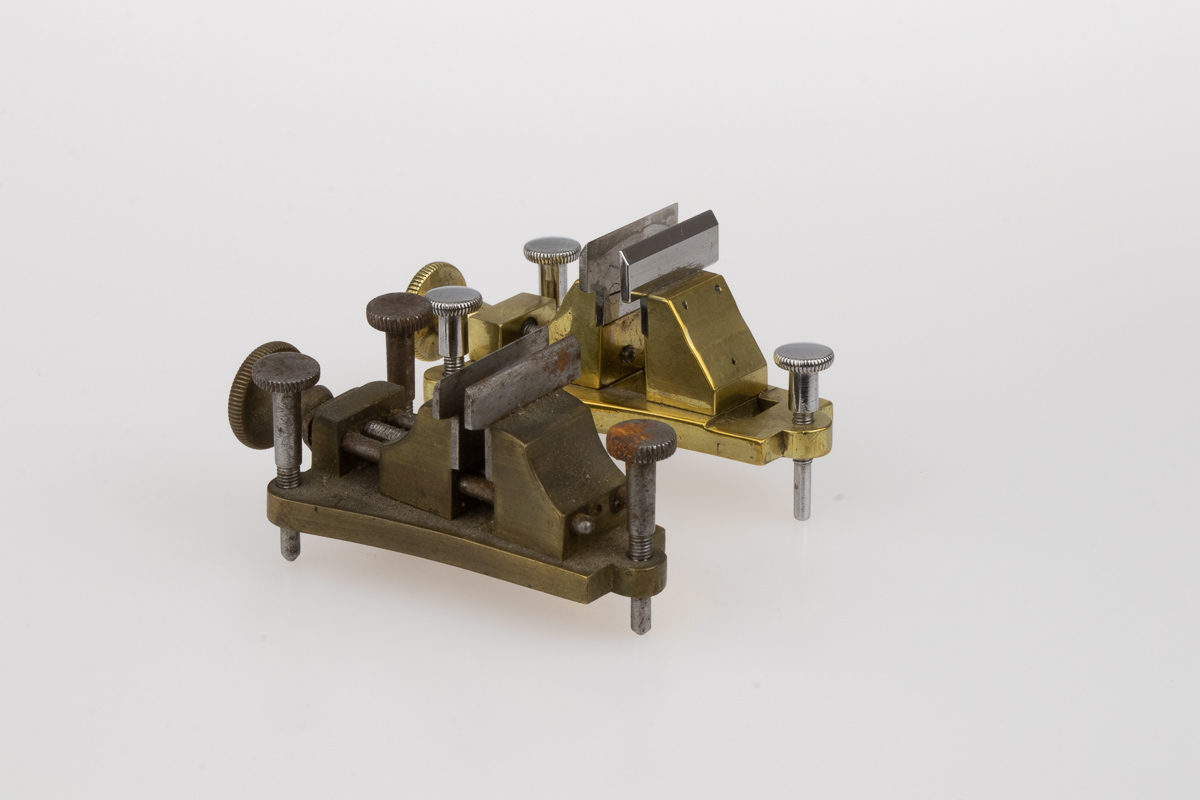

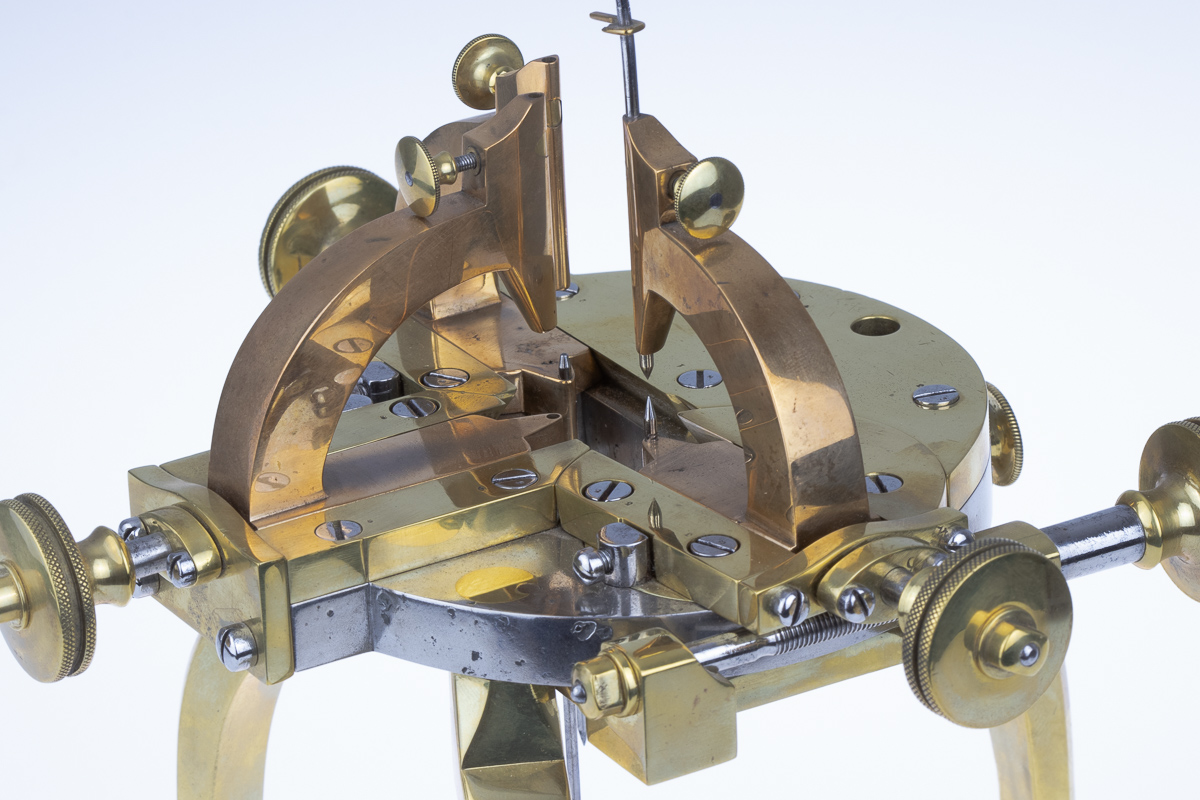

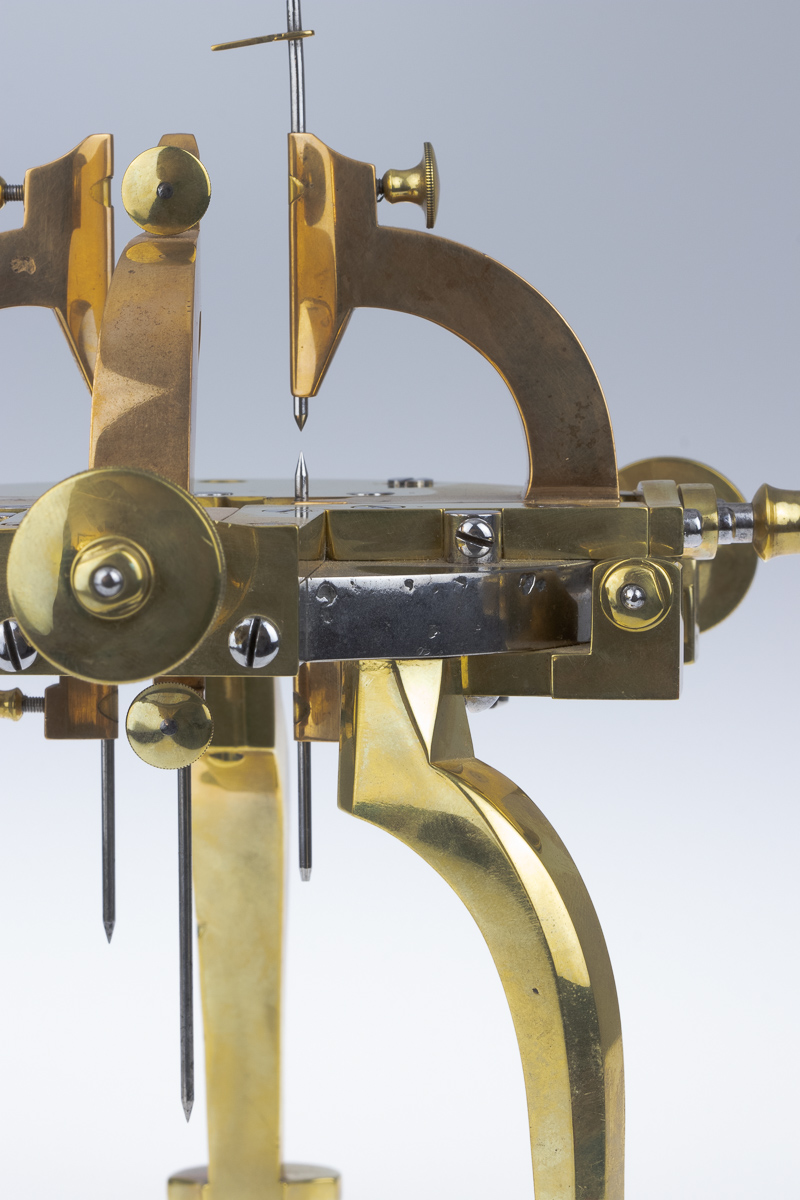

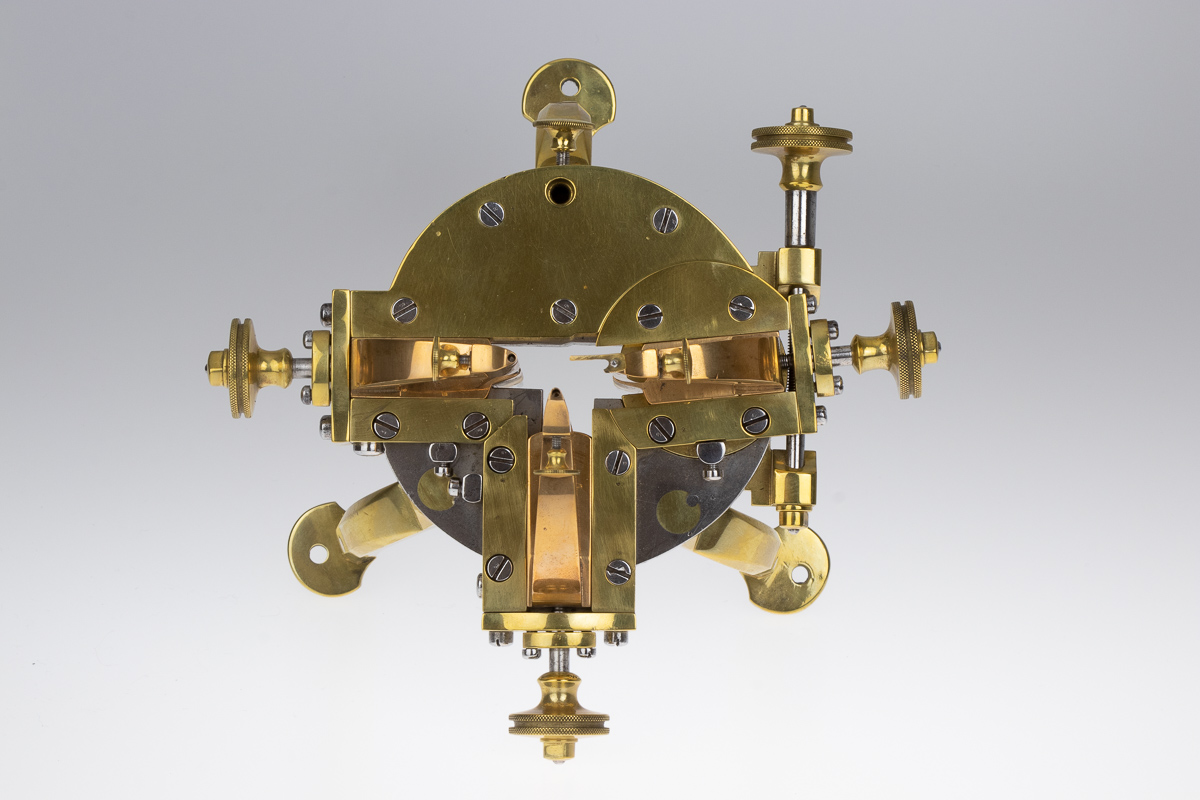

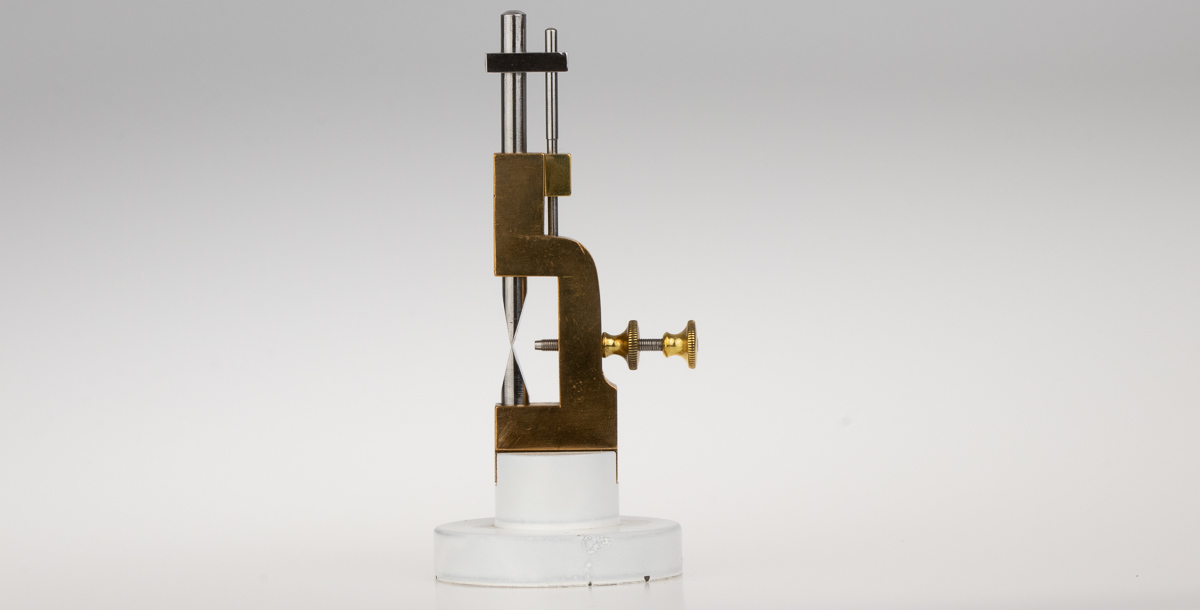

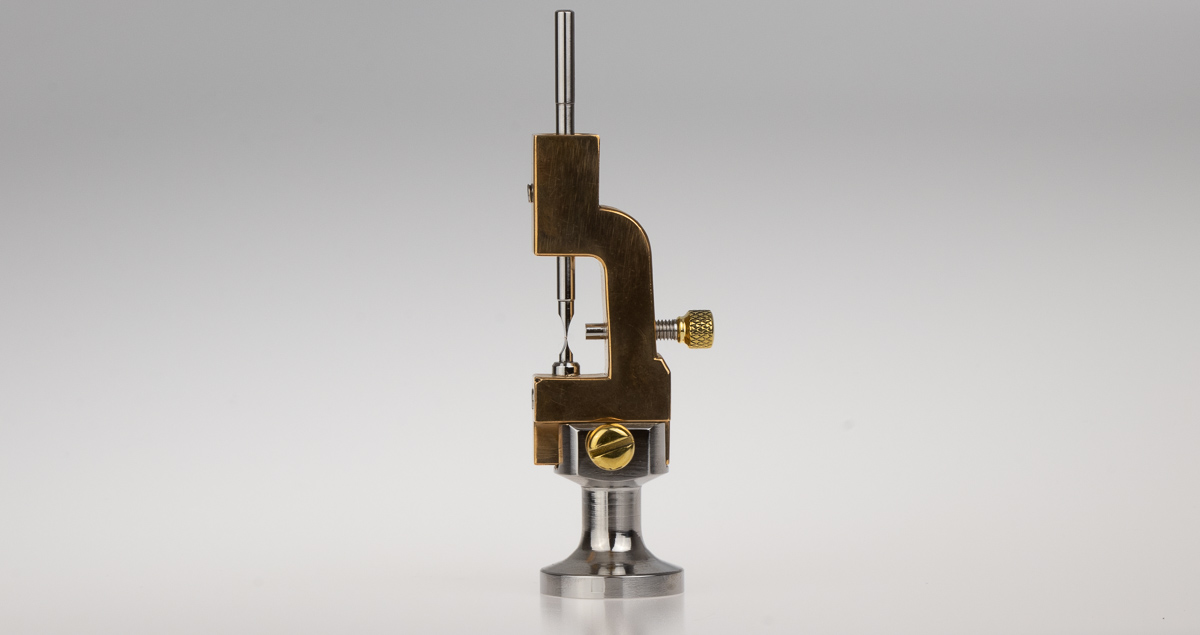

A centering tool

A mainplate pivot hole would have been alined with the lower spindle, then the bridge or cock screwed in place on the mainplate would have been marked with the upper spindle (centre punch), assuring the resulting wheel or barrel to be added would be perfectly perpendicular between bridge and plate.

The above tool is fixed on three legs, below the tool is held in a bench vice on the square section.

A similar centring tool as shown above but with multiple spindles.

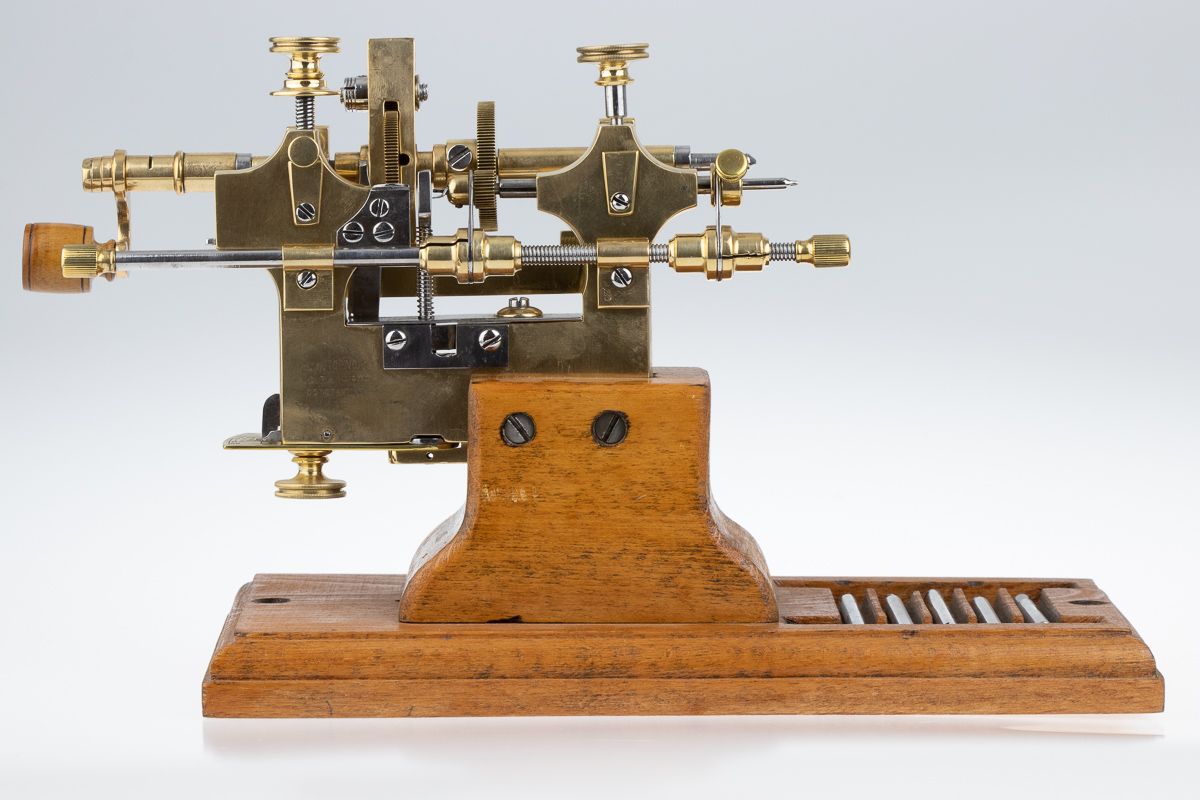

A lathe for turning between points or pivots.

Below 2 pivot lathes before and after restoration.

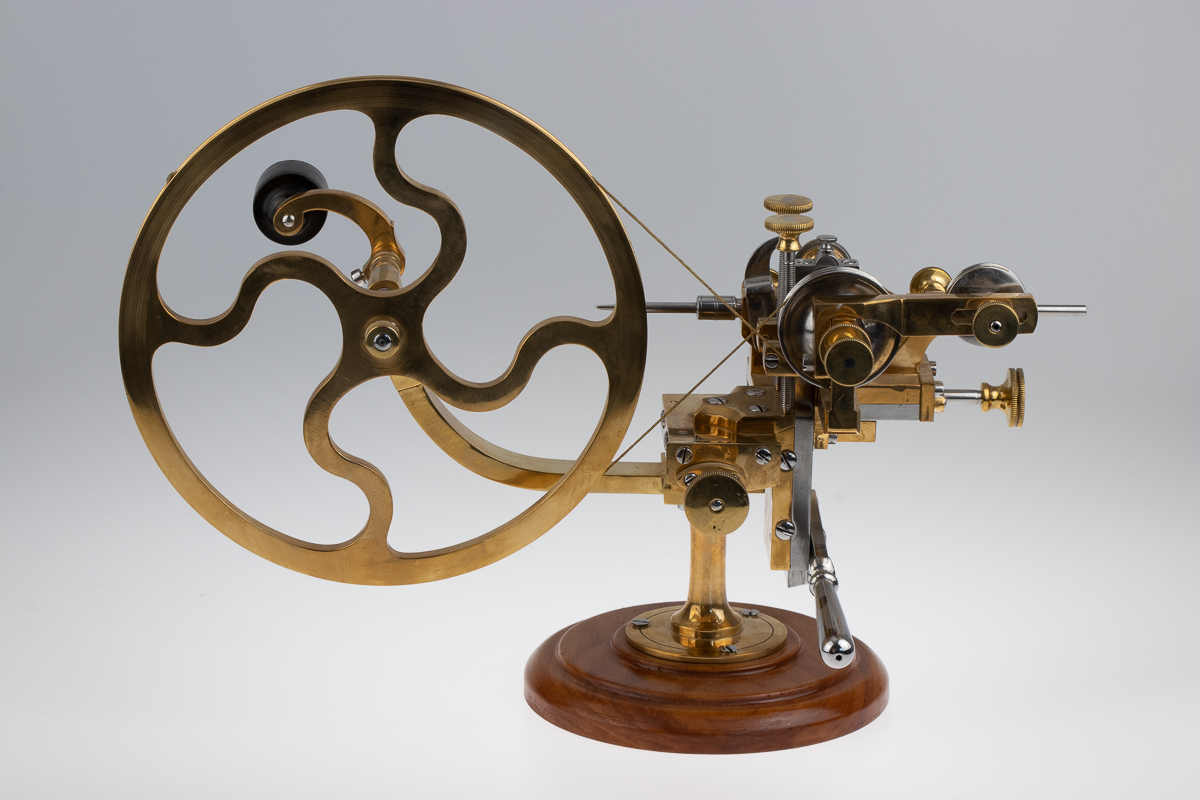

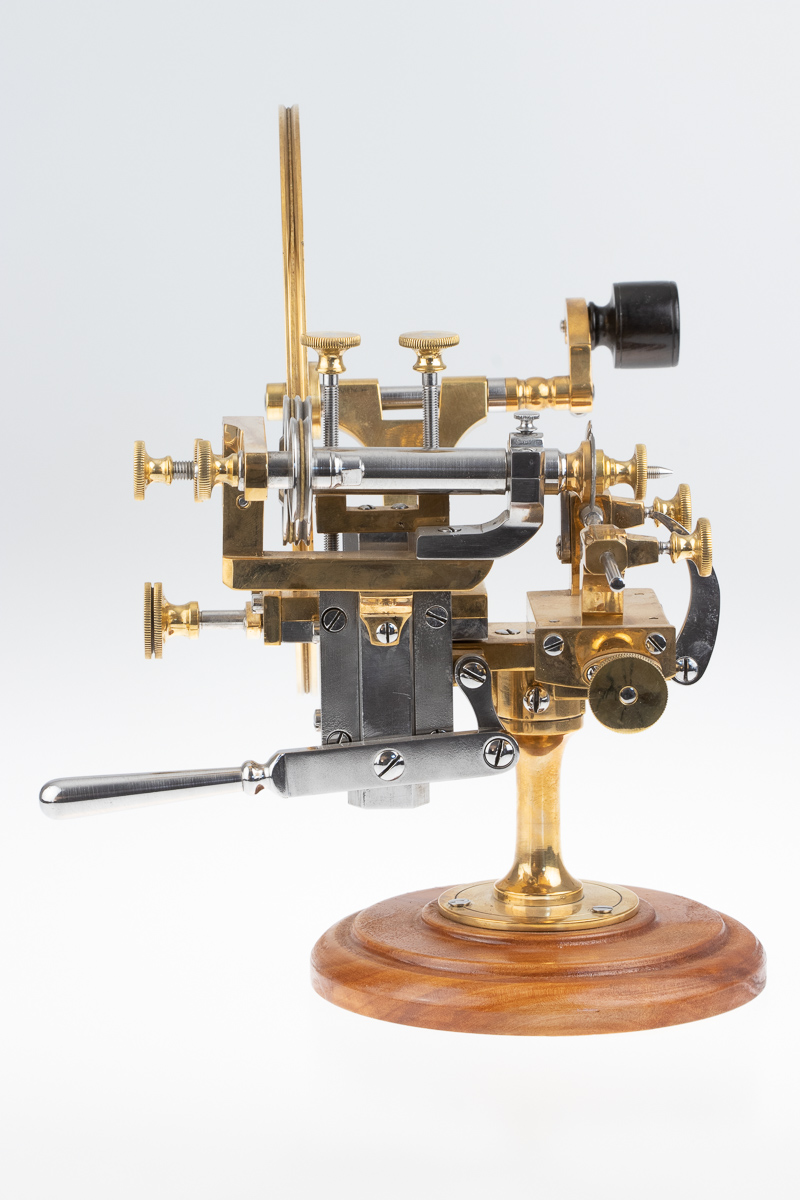

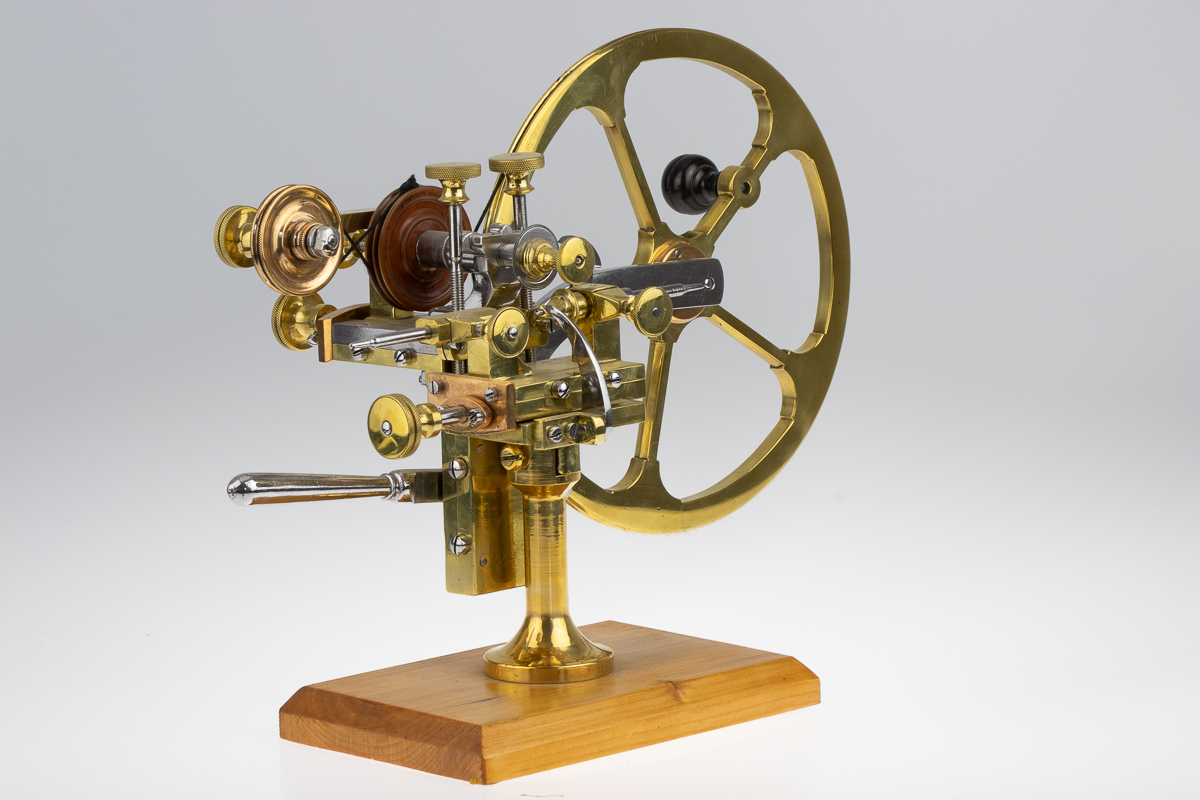

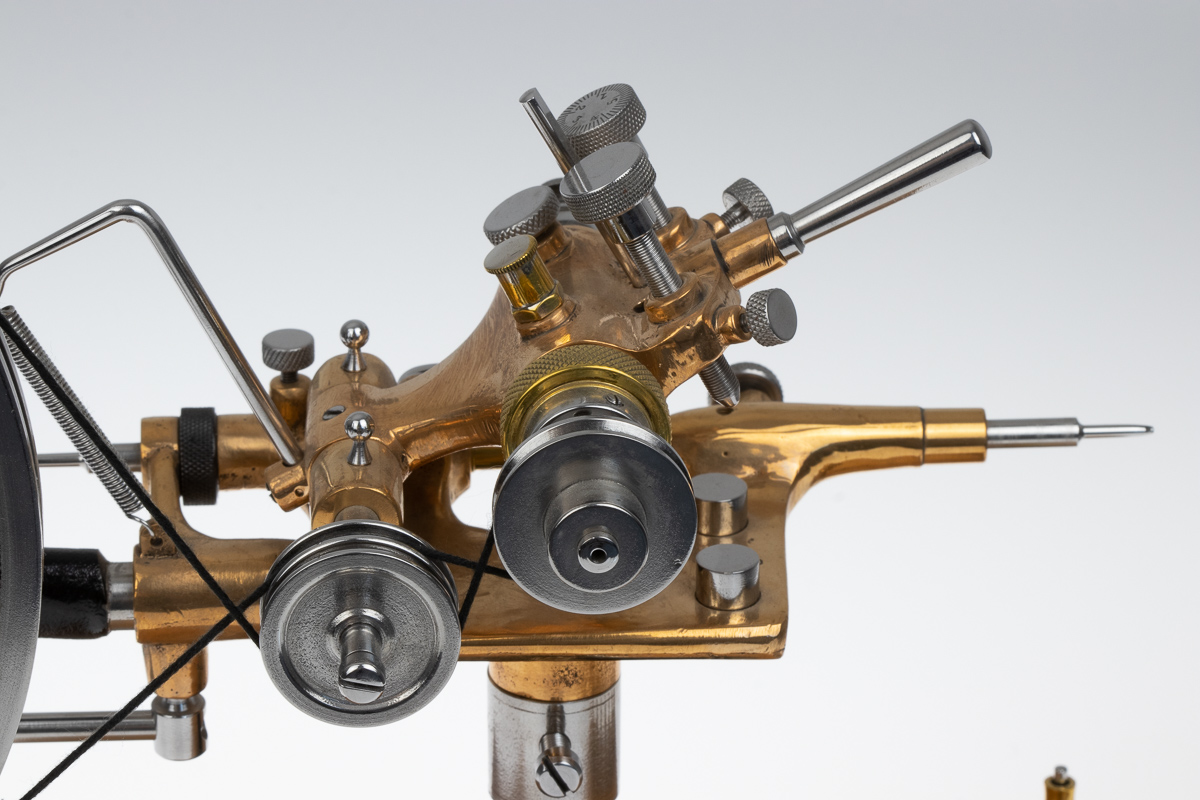

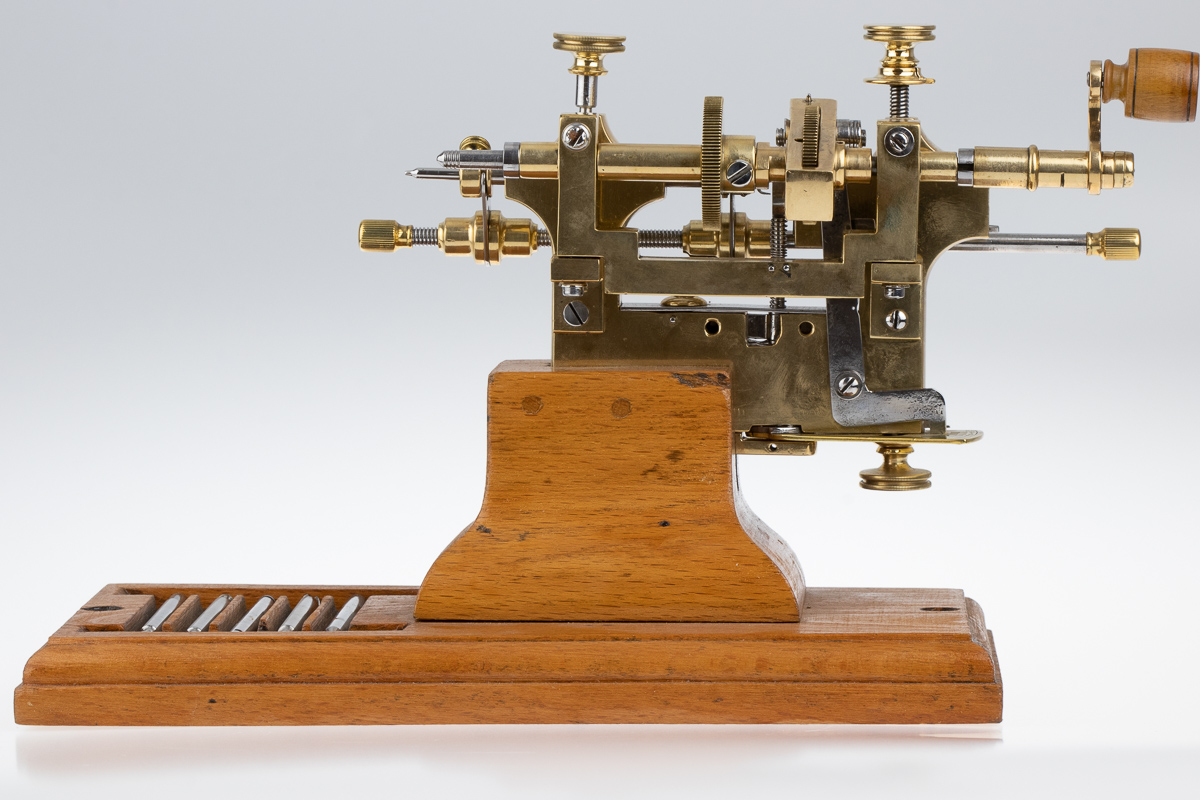

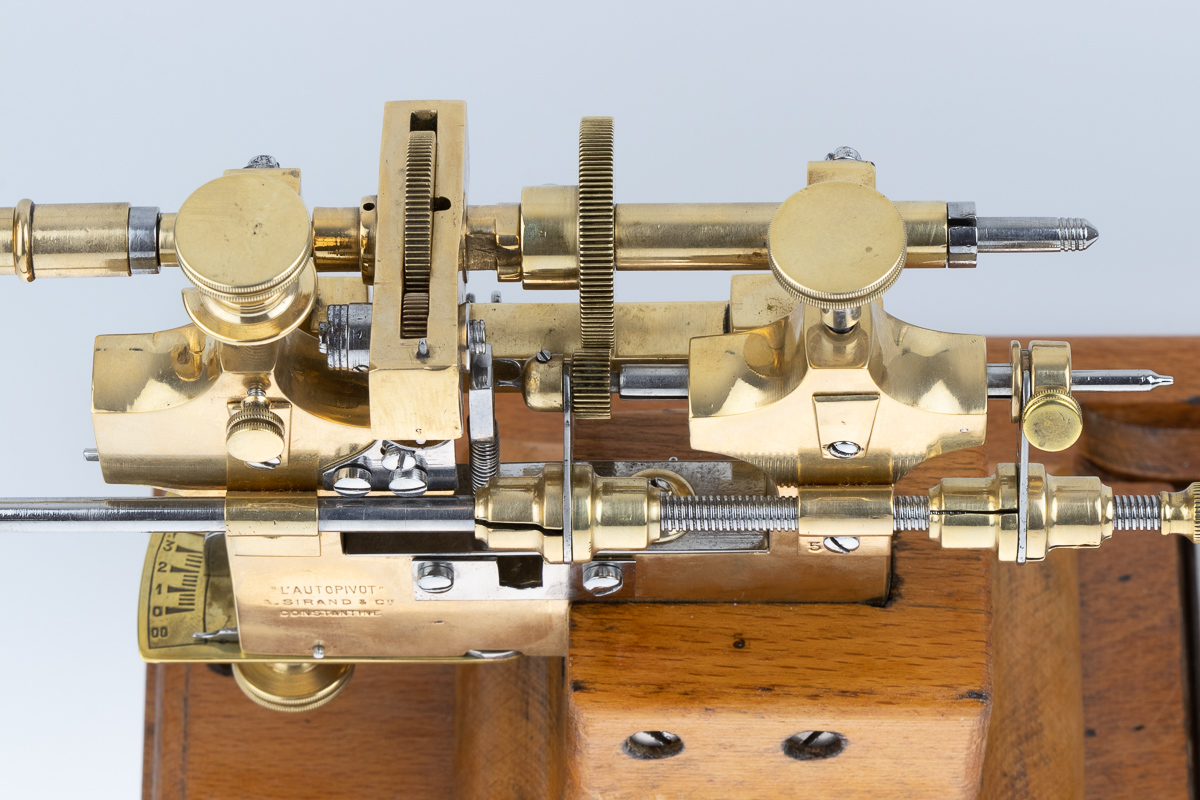

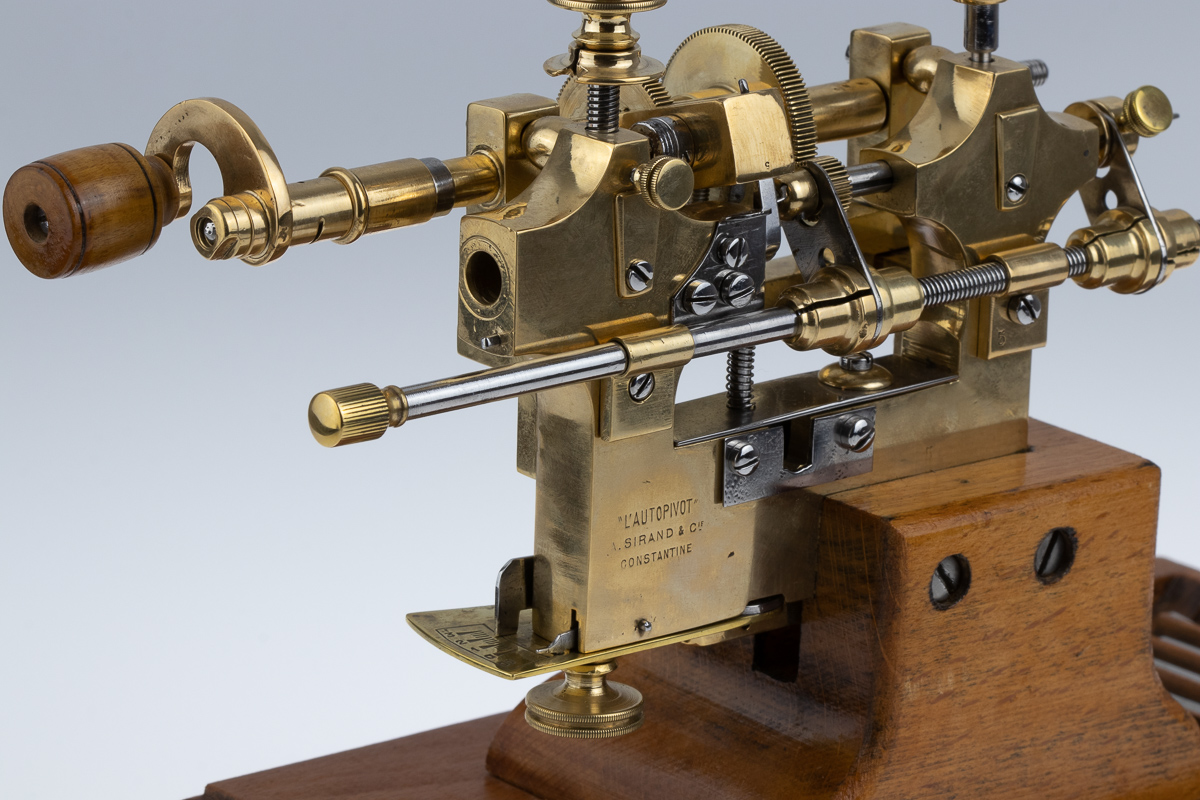

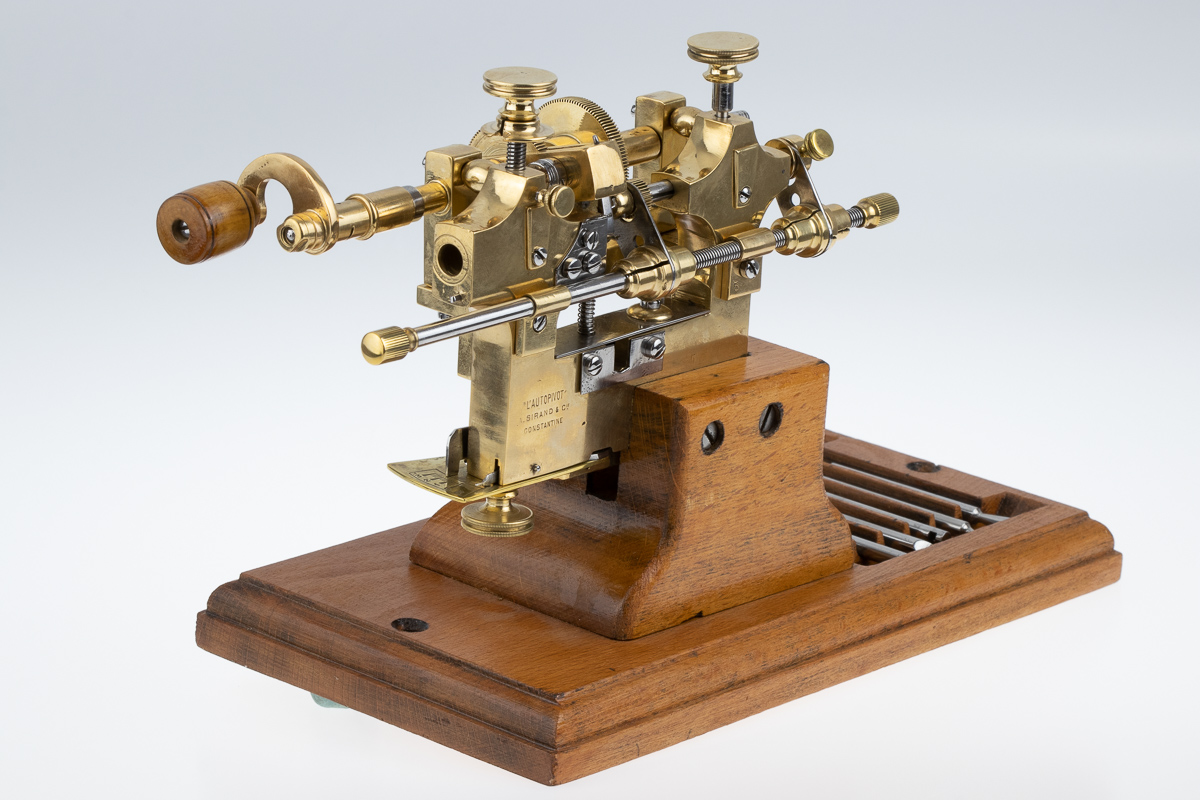

The Jacot Tool

A special-purpose lathe used by watchmakers to burnish, polish and adjust both train wheel and balance pivots.

A Jacot tool powered by a drum/spring system. The small ring would be pulled by the finger to drive the wheel or balance.

A special Jacot tool powered by an elaborate crank system.

Pocket watch bow pivot cutter

The purpose of the tool was to mill the pivots of the bow (upon which a chain would be attached to).

A hand made, balance wheel poising tool with hardened steel jaws.

Examples of before and after restoration.

Tool for holding balance wheels (and supporting balance cocks) whilst the balance screws were manipulated.

A balance spring vibrating tool.

The balance shown under the glass crystal would oscillate at a defined frequency. A watchmaker would then regulate the length of a new balance spring associated to a balance assembly using the lower balance as a reference before placing his balance into a watch. He would slowly reduce the length of the balance spring being supported by the upper tweezer like fingers until the the new balance was oscilating in harmony with the lower master balance assembly.

Canon pinion tightening tools.

Inclined micrometer

Press tool

To learn more about the collection click here www.petites-machines.ch