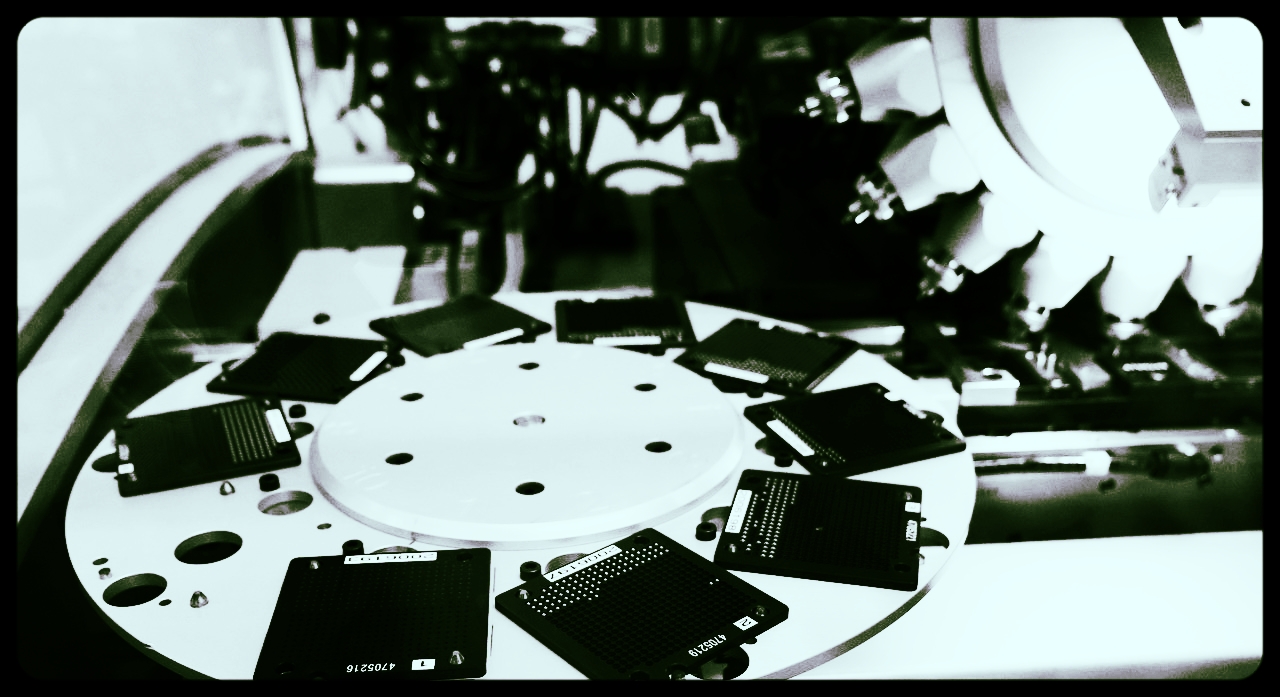

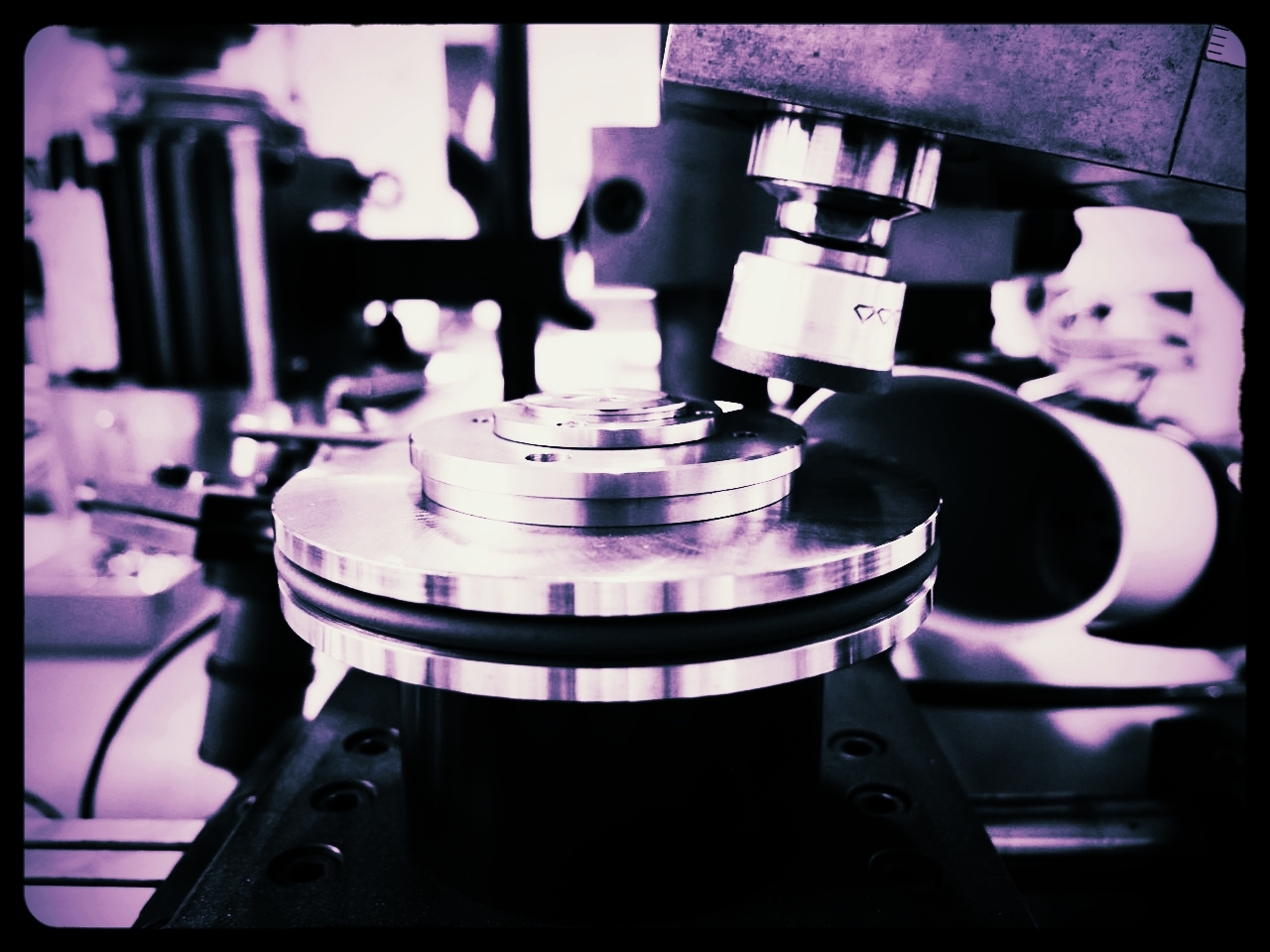

The material below illustrates the development and manufacture of movements is non-exhaustive. It helps to explain part of the complexity of the process as well as some of the people behind it.

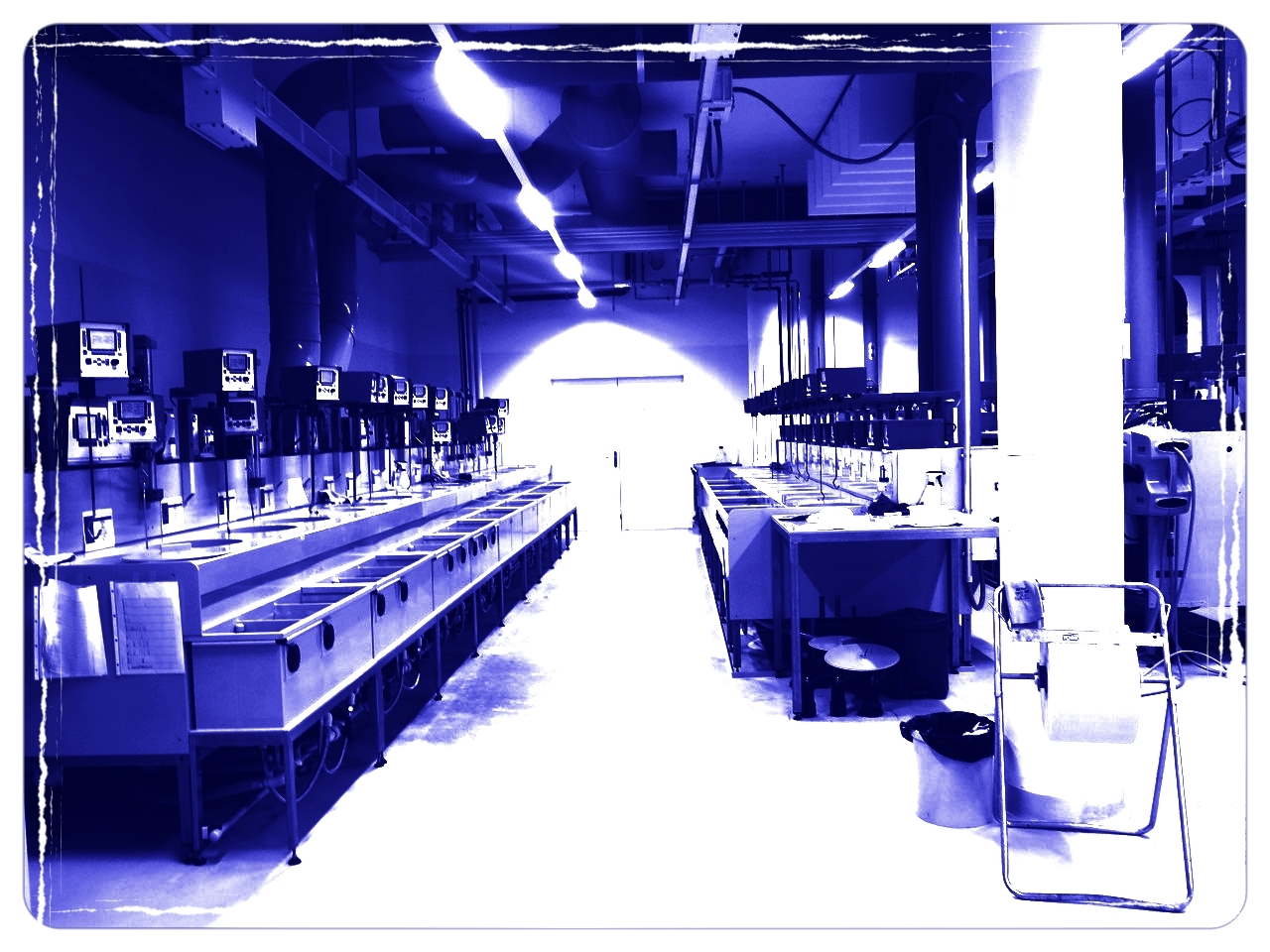

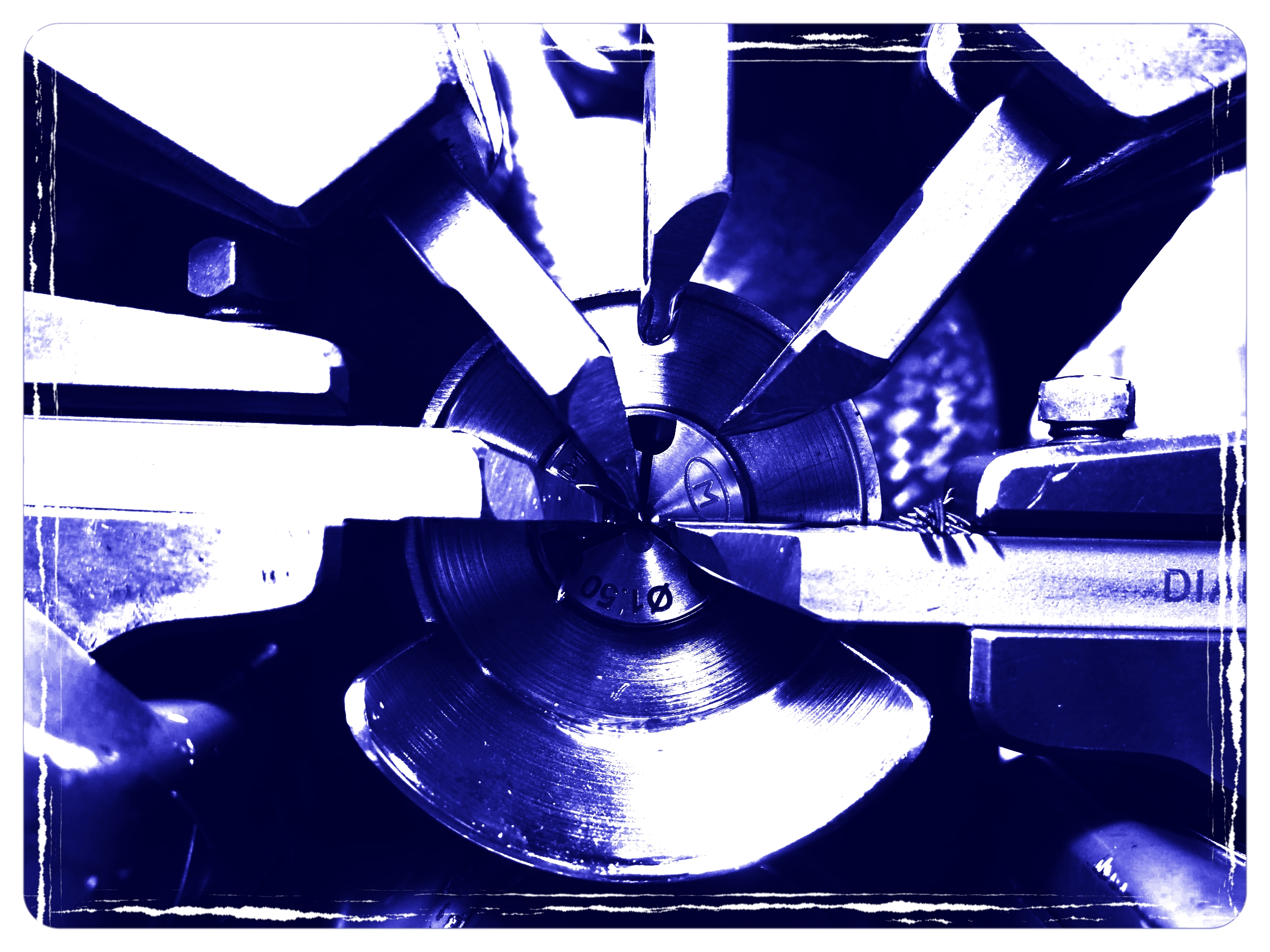

Each movement manufacture has variations on the same themes which change in relation to quantities and product positioning. The movements developed here are targeted to the top level of industrial movement manufacturing.

Terminology for the order in which movements are assembled.

T zero (T0) pre-assembly of bridges, mainplates and small components

T one (T1) assembly of the movement and final adjustments

T two (T2) casing up of the movement with dial, hands and in case

T three (T3) adding the bracelet and buckle, presentation box and certificates etc

The above study was made using the Vaucher manufacturing facility in Fleurier, Elwin in Belprahon and Atokalpa in Alle all based in Switzerland.